Metalock Cold Casting Repairs In Situ

Every day, around the world, someone in an industry like yours relies on our specialist cold repair techniques for cracked or broken components made of cast iron, steel or aluminium.

Why? When you need to get a business-critical plant working again as soon as possible, and only a cold repair will do, you can count on the proven Metalock process.

Cold Repair Service For Broken Metal Components

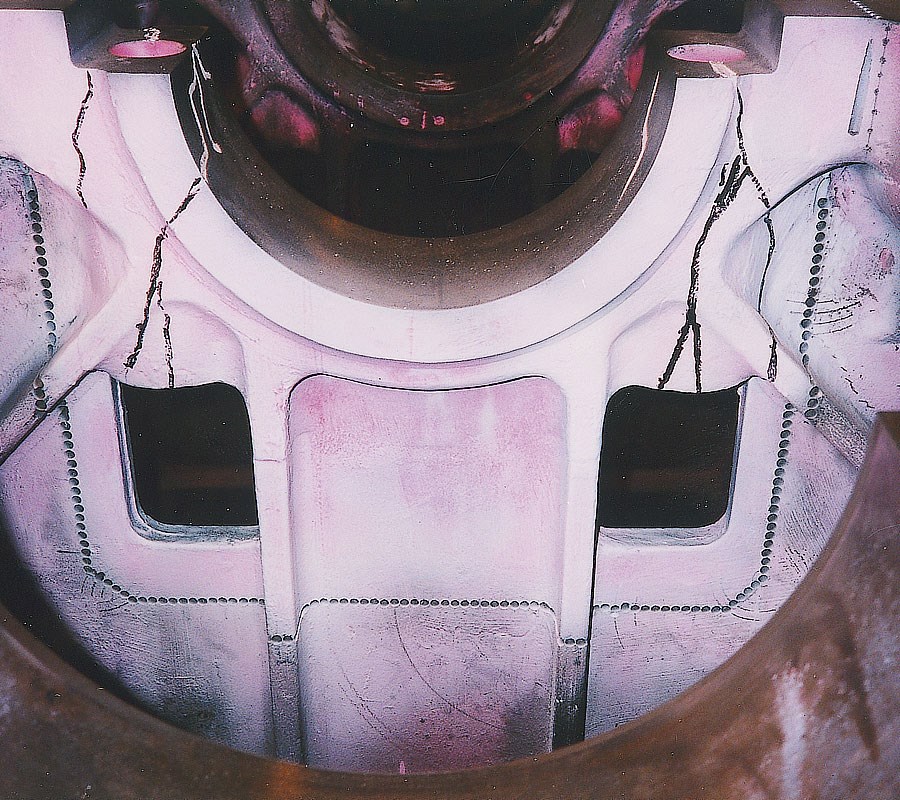

Our unique Cold Repair Process, developed in the early 1930s is based on sound engineering principles. It avoids stress problems associated with welding and maintains original alignment, which reduces the need for costly re-machining after repairs.

Advantage of Casting Repairs In Situ

Metalock customers value the advantages of our proven cold repair method. These include the following:

- We usually do the work on site – saving you time and avoiding dismantling.

- Maintenance of alignment and original surfaces.

- Dampening and absorption of compression stresses.

- Spreading of tensile strains.

- Distribute load away from fatigue points.

- Provide a low coefficient of expansion in relation to the repaired metal.

- Because the repair is completely cold, it doesn’t introduce fresh stresses.

The Benefits

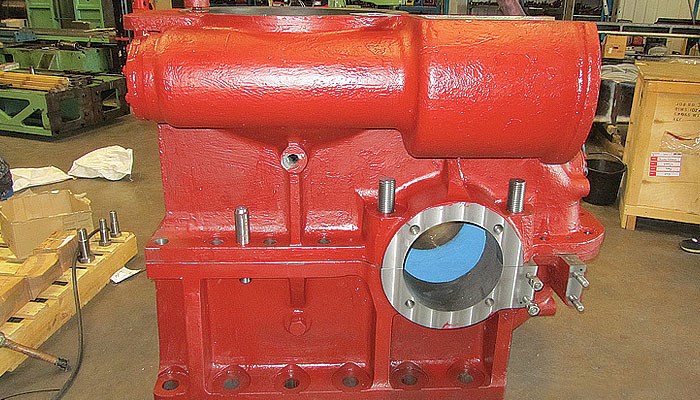

From cracked gearboxes to fractures in press frames or a cracked bridge parapet and structure repairs, damaged castings mean inconvenience, cost, and delay. That’s when our cold casting repairs prove their worth:

- A swift response worldwide 24/7.

- A proven solution-focused approach.

- Carried out on site or in our workshops.

- Workshop-quality on-site repairs.

- One source for your casting repairs.

- More than 70 years of engineering expertise means you can trust us.

Submit an Enquiry

Find out how our experience with on-site casting repairs can help save you time and money.

With technicians strategically located throughout the group, we are organised to provide a rapid response service to deal with emergency breakdowns 365 days of the year.