Crankpin Machining On site & In Situ

Whenever there is an engine malfunction while in service, there is always damage to the engine, it can range from bearing failure causing crankshaft damage or even a conrod smashing through the crankcase door causing serious damage. The result is always the same - downtime and costly repairs.

Wherever you are in the world the Metalock Engineering Group offer a wealth of on-site machining skills and experience to salvage diesel engine crankshaft main-bearing and big end journal diameters on large and small engines.

We Have Been Doing This Type of Work For Decades.

If you have a problem we are just one click or a phone call away. We have service centres around the world that offer a 24/7 - 365 response to emergency breakdown situations wherever your location.

Based on decades of challenging work for marine propulsion and power, as well as industrial power generation applications, we know we can usually solve your crankpin machining in situ challenge without resorting to the costly removal of the crankshaft.

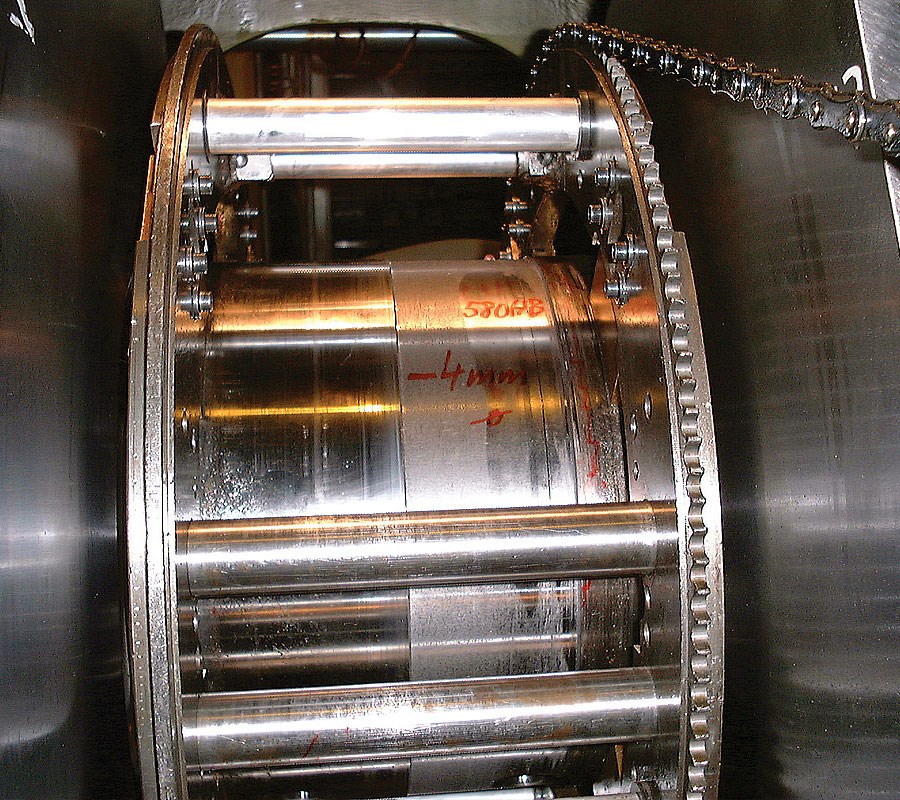

Machining of crankpins

All crankshaft re-machining is in accordance with our Metalock Engineering process description ‘Machining of crankpins’ and is to result in satisfactory surface finish within the original engine manufacturer tolerances. Final inspection includes magnetic particle inspection, surface hardness, dimension, run-out, surface finish and crank web deflection.

All readings reported and recorded for our customers quality records.

Our Range of Capabilities Include the Following:

- Crankshaft inspections including Hardness Testing and Dimensional Surveys.

- NDT inspection, including Magnetic Particle Inspection (MPI) & Dye Penetrant.

- Crankshaft Straightening.

- Crankshaft Heat Treatment to reduce high hardness values to enable re-machining.

- Machining of damaged journal fillet radii.

- Journal regrinding and superfinishing to manufacturers’ specifications.

The Benefits

Wherever in the world your plant or vessel is located, you get all the usual Metalock Engineering Group benefits when you entrust your in-situ crankpin machining to us:

- A proven solution-focused approach.

- 24/7 worldwide service – call us anytime to save time and money by avoiding costly workshop repairs.

- Build and protect your professional reputation with our support.

- Workshop-quality machining on site.

- One source for all your on-site machining.

Nearly 70 years of engineering expertise – you can rely on us to complete the most challenging projects on time, on budget and to the highest quality standards.

Submit an Enquiry

How can we save you time and money, and get your plant or vessel earning money again as soon as possible?