1. Contact surfaces

1. Contact surfaces

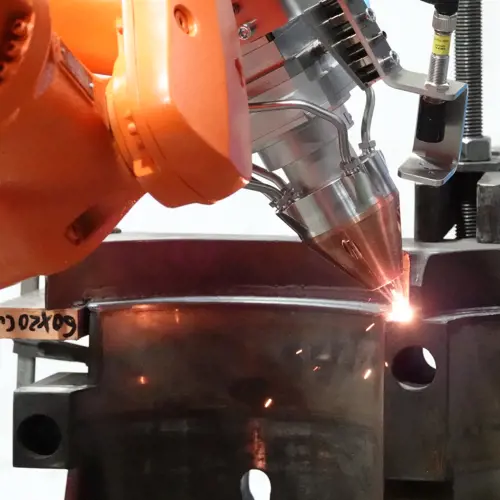

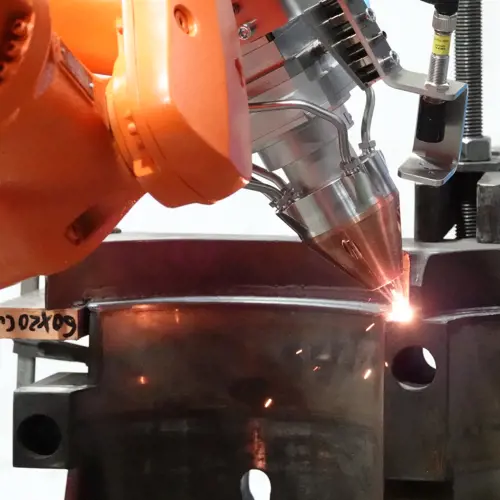

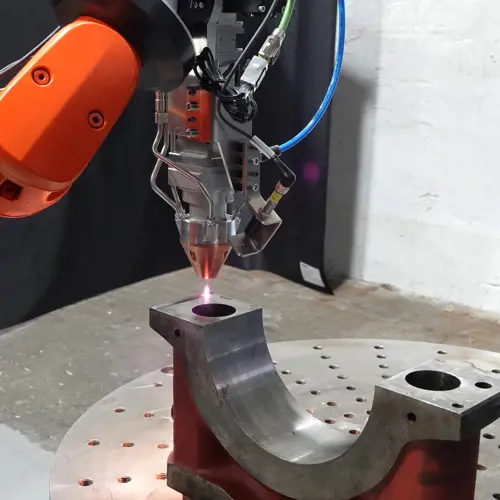

Customer project 1: Overlay welding of contact surfaces of a tool holder

Customer project 1: Overlay welding of contact surfaces of a tool holder

Weld seams that are applied side by side in several tracks along the circular segment

Weld seams that are applied side by side in several tracks along the circular segment

Result: A defined, homogeneous weld deposit

Result: A defined, homogeneous weld deposit

Result: A defined, homogeneous weld deposit

Result: A defined, homogeneous weld deposit

2. Partial joint of a pivoting bearing

2. Partial joint of a pivoting bearing

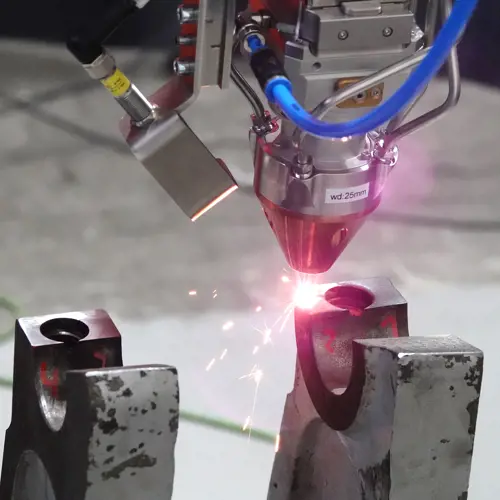

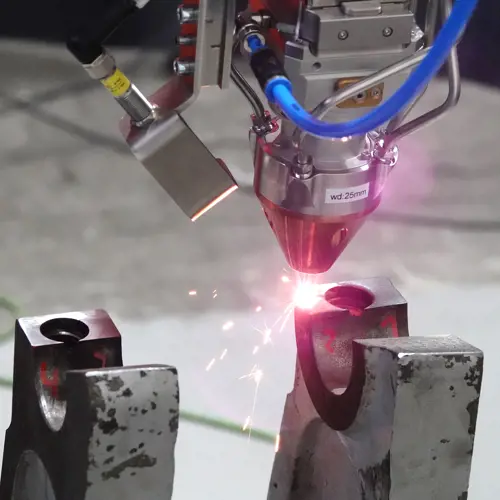

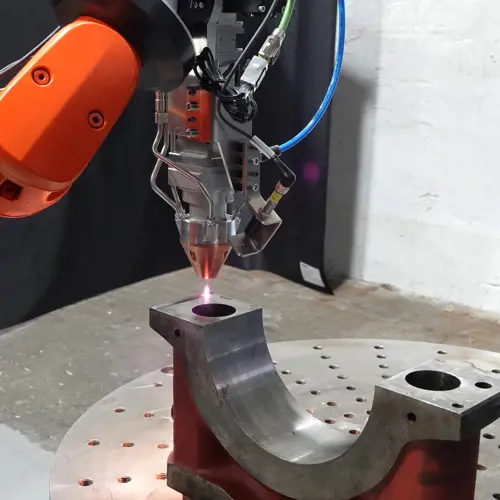

Customer project 2: Overlay welding of the partial joints of a press spherical plain bearing

Customer project 2: Overlay welding of the partial joints of a press spherical plain bearing

Programmed process in paths over the surface to be welded

Programmed process in paths over the surface to be welded

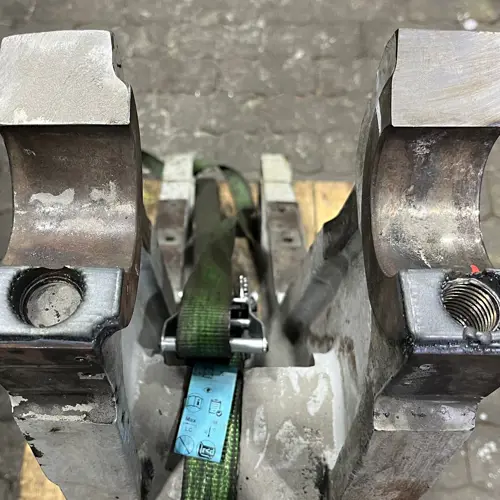

All four end faces must be build-up welded

All four end faces must be build-up welded

End faces 1 and 2 of 4 completed

End faces 1 and 2 of 4 completed

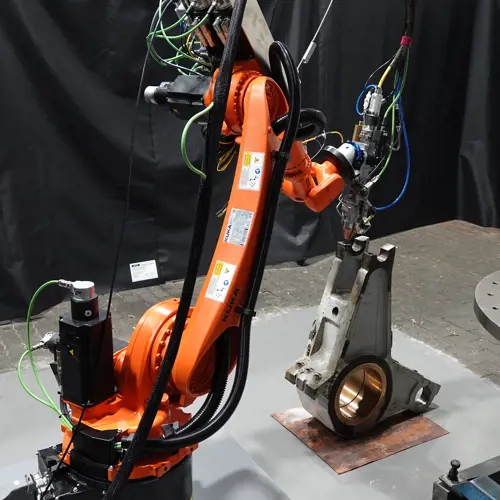

Overall arrangement with welding robot

Overall arrangement with welding robot

Face 1 of 4 in detail

Face 1 of 4 in detail

End faces in detail

End faces in detail

3. Contact surfaces of bearing caps

3. Contact surfaces of bearing caps

Customer project 3: Overlay welding of the bearing surfaces of bearing covers of a marine engine

Customer project 3: Overlay welding of the bearing surfaces of bearing covers of a marine engine

Precise application of the welding strips after prior programming

Precise application of the welding strips after prior programming

Result

Result

Get in contact

How can we help you? We offer a 24/7 worldwide emergency response. Please select from the options below to contact us.

Submit an Enquiry Office Locations Quick Contacts Careers