The Cold Metalock Process – Metal Stitching

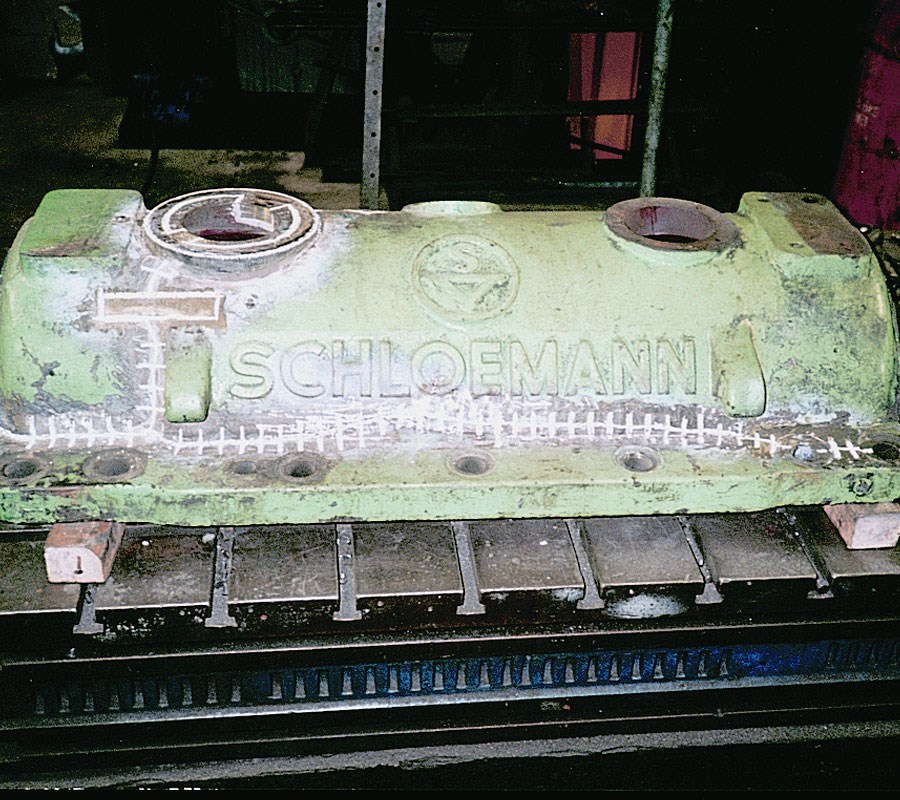

If you have cracked cast iron components, Metalock Engineering should be your first port of call. We use a sophisticated technique called the Cold Metalock Process, which is widely regarded as the best method to repair cracked and broken cast iron components.

The Cold Metalock Process involves peening keys into prepared apertures. Formed from special nickel alloys, the keys are highly ductile and can be peened into a metal-to-metal condition, becoming almost integral with the parent metal. One of the main advantages of this process is the fact that no heat is used at all. This is important because methods using heat can introduce additional stress or distortion.

We have helped businesses with our cracked cast iron repair services in many industries over the years, but it is the marine industry where we have done a lot of our best work. We have helped many ship owners make enormous savings and save time with our prompt action that saves capital plant and equipment following a breakdown. Our cast iron repair service can then give this equipment a new lease of life and provide many more years of service with peace of mind, knowing that the cast iron is once again strong and reliable.

The Metalock Engineering Approach

Metalock Engineering is proud to offer a 24/7 global response service. We have technicians placed strategically around the world ready to travel at short notice, meaning that we can provide rapid response and deal with emergency breakdowns any day of the year, no matter where you are located.

In addition to this, cast iron repairs can often be carried out on-site. This means that equipment may not have to be removed from its working position and transported to a workshop - this can also help you save money.

Our team of technicians is also highly experienced and has worked in a wide range of industrial settings, meaning that they will be able to perform to a high level and minimise disruption to your business while repairs are being carried out.

The Casting Repair Process

The Casting Repair Process

The Metalock process is based on sound engineering principles which have been accepted for over 70 years.

- Holes drilled along the line of fracture, tapped and filled with studs.

- Holes drilled at right angles to the fracture.

- Holes drilled to form shape of Metalock keys.

- Layers of keys peened into metal-to-metal condition.

The Casting Repair Process

The Casting Repair Process