We are the largest on site machining engineering group in the world and are considered pioneers when it comes to specialised, complicated, and technically demanding mechanical engineering and mechanical repair projects for businesses in wide-ranging industries.

What is a Diesel Engine Bedplate?

Diesel engines are highly complex with many components. The engine bedplate is the structural frame that supports and aligns the crankshaft and main bearings. Typically made from cast iron or steel, the bedplate is the foundation of the engine and distributes loads evenly.

Although built to withstand huge forces during operation, there are a number of issues that can arise from prolonged stress, misalignment, and environmental factors. This can include cracks, breaks, and general wear. It is vital that swift and efficient repairs are carried out to maintain performance and avoid further damage.

Industries That Use Diesel Engine Bedplates

Diesel engine bedplates are used in a number of industrial sectors and play a pivotal role in many key processes. A few of the most common industries include:

Marine: Diesel engines are used in many ships and submarines with the bedplate used to support high-performance crankshafts for propulsion and auxiliary power in challenging marine environments.

Mining & Construction: Diesel engines are used in many different types of mining and construction equipment, including trucks and excavators. Bedplates are vital for stable and reliable operations in difficult conditions.

Manufacturing: Manufacturing operations and processing facilities use industrial diesel engines that require durable bedplates to handle continuous operation and high loads.

Oil & Gas: In the oil and gas sector, diesel engines provide power to drive compressors, pumps, and other industrial equipment. Damage to the bedplate can compromise safety and efficiency, so repairs must be carried out as quickly as possible.

Power Generation: Diesel engines are used as primary or backup generators in power plants, and the bedplate is key for ensuring uninterrupted power.

Common Causes of Cracked or Broken Diesel Engine Bedplates

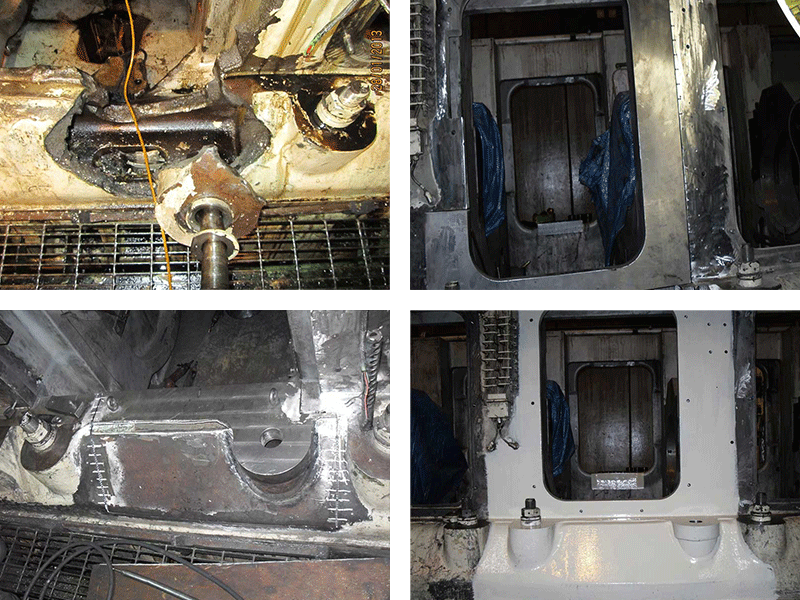

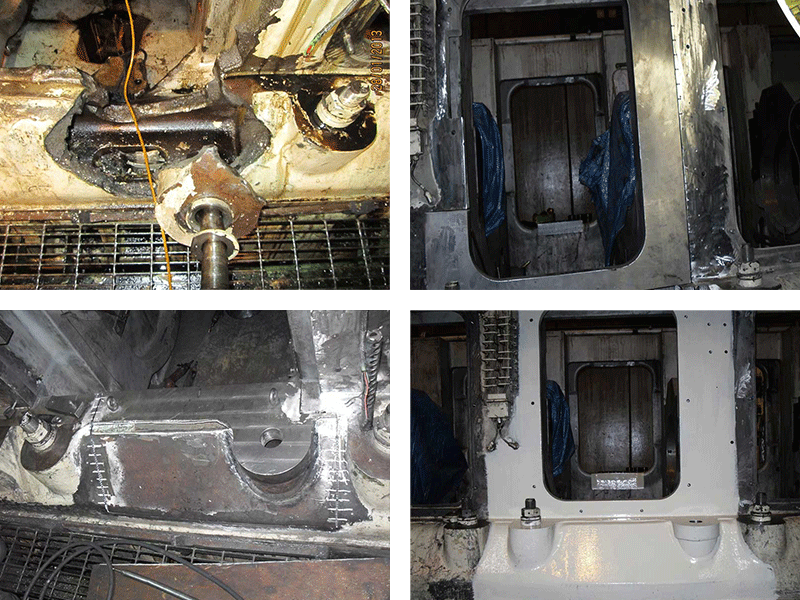

Metalock Casting Repair Department Stork Werkspoor diesel engine block – broken crankcase door repair

Cold Metalock Repair on broken Crankcase door following engine failure and broken con-rod breaking out the side of the engine block

Diesel engines are used in challenging environments with significant stresses that can lead to cracks or complete failure. A few of the most common causes include:

Corrosion & Wear: One of the most common issues is corrosion and wear. This can be a result of exposure to moisture, oil, and chemicals that create corrosion and wear, which can reduce the structural integrity of the diesel engine.

Impact Or Overload: Breaks and fractures in the bedplate can sometimes occur due to accidental impact and operating the engine beyond its designed capacity.

Material Fatigue: Fatigue can occur from continuous usage, stress, vibrations, and environmental factors. This can weaken the material, which makes it prone to cracks and damage.

Misalignment: Misalignment of the crankshaft or other internal components can create uneven loads on the bedplate, which increases the risk of damage occurring.

Operational Stress: Continuous operation of diesel engines leads to heavy loads and vibrations that can create stress points. Over time, this can lead to cracks and fractures.

Thermal Expansion & Contraction: Regular heating cycles from continuous operation can create thermal stress, which results in material fatigue and cracks. This is common with cast iron bedplates.

Diesel Engine Bedplate Repair Services from Metalock Engineering

With over 70 years of experience in engine repairs, the Metalock Engineering Group are considered experts when it comes to bedplate repair services. Engine availability is a critical requirement in many industries, but things can go wrong, and even a well-maintained engine can break down. In these situations, you need a repair specialist that you can trust.

One of the main benefits of using Metalock for your repair needs is our onsite diesel engine repair service. We can carry out repairs in a power generation plant, in a dry dock, or even out at sea. This means that we can carry out the repair quickly, and it prevents the need for equipment dismantling and parts to be sent away for repair.

We also have a global 24/7 repair service. We have a presence in over 100 countries and have our technicians spread out and ready to travel at short notice, helping to speed up repair times and keeping downtime to a minimum. We make ourselves available 24/7 and 365, so you can contact us at any time when you have a broken or cracked bedplate, and we will be ready to get to work.

Metalock Engineering uses advanced repair techniques that ensure bedplate repairs are carried out swiftly, efficiently, and safely. We can often restore diesel engine bedplates to their original specification, prolonging the life of your equipment and avoiding the need for expensive repairs.

We can often fix cracks using our patented metal stitching technique. This is a cold repair technique that can prevent distortion or further damage, which can be a risk with welding and other heat-based repair techniques.

In addition to metal stitching, we can restore diesel engines with our precision machining services to restore alignment, recondition worn bedplate surfaces, and apply protective coatings to prevent further damage from corrosion. No matter what issue you are experiencing with your diesel engine bedplate, we are confident that we can resolve the issue and get you fully operational before long.

Contact Metalock Engineering Today for Diesel Engine Bedplate Repairs

When you experience an issue with your diesel engine bedplate, it is vital that it is resolved as quickly as possible to prevent downtime and get fully operational. Metalock Engineering is the sensible choice as we have extensive experience in diesel engine bedplate repairs using our advanced techniques and technologies. In addition to this, we can often carry out repairs in situ and have technicians located all over the world. Get in touch today to find out more.