Engines must be properly aligned to avoid damage to key components and to maintain optimal performance, so this is a service that is essential for businesses in many industries. Keep reading to find out more.

What is Engine Alignment?

So, what exactly is engine alignment? This is a process that involves making sure that all of the internal components are in the right position in relation to one another and surrounding equipment. Alignment is key for minimising mechanical stress and allows for smooth operation.

Even the slightest misalignment can cause significant issues, including excessive vibrations that can cause stress on bearings, accelerate wear on key internal components, energy loss, and increased risk of breakdown (and expense repairs).

The Importance of Engine Alignment

Engine alignment is an essential service for any engine that is used in an industrial setting. This is because mechanical stress and environmental factors can cause misalignment over time, so even a well-maintained engine can become misaligned. Where you get your engine aligned regularly so that issues are resolved quickly, you will benefit from the following:

Avoid costly repairs: Regular engine alignment prevents damage to key engine components. This can save you money in the long run as you can avoid expensive repairs and the costs associated with downtime.

Extend engine lifespan: Alignment is a maintenance task that can extend the lifespan of your engine. By ensuring all components are aligned, you prevent damage that can shorten your engine's lifespan and avoid having to replace the engine prematurely.

Improve efficiency: Engine alignment can improve the energy efficiency and overall performance of your engine by reducing wear and vibrations.

Improve safety: Finally, engine alignment reduces vibration and wear, which reduces the risk of catastrophic failures and ensures safe operation.

Common Causes of Engine Misalignment

All engines can become misaligned over time, particularly those that are in constant operation and/or operate in challenging environments. A few of the main causes include:

Vibrations: Operational vibrations can cause the internal components to shift out of position over time.

Wear and tear: General wear and tear on the bearings, couplings, and other components can lead to misalignment.

Thermal expansion: Components can expand or contract because of temperature changes, which can lead to misalignment.

Improper installation: The slightest inaccuracy during installation or assembly can lead to components that are not properly aligned.

Industries We Serve

We have experience in performing engine alignment services for businesses in many industries. Here are a few of the most common:

Marine and offshore: Propulsion systems and auxiliary machinery require accurately aligned components for the performance and safety of engines in various vessels.

Power generation: Turbines and generators in power plants use engines that rely on precise alignment for continuous energy production.

Manufacturing: Engines are used in production lines and industrial equipment that must be precisely aligned for continuous operation.

Oil and gas: Engine alignment is key for several components in refineries, pipelines, and offshore rigs, including compressors, pumps, and generators.

Engine Alignment Services from Metalock Engineering

Regular engine alignment is a vital service for businesses in wide-ranging industries and can help save money in the long run while helping prevent costly shutdowns. As such an important service, it is vital that you know how to choose a reliable alignment partner. Here at Metalock Engineering, we have extensive experience in engine alignment and have provided this service for businesses in wide-ranging industries.

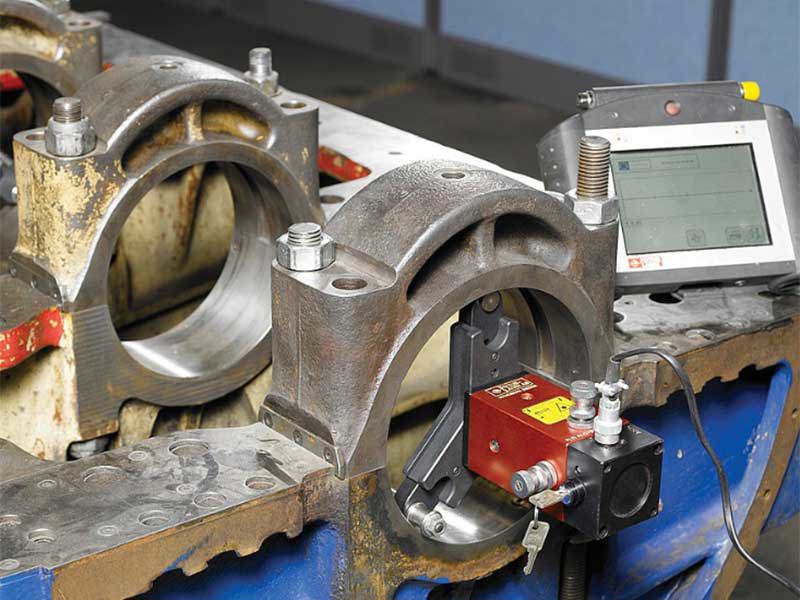

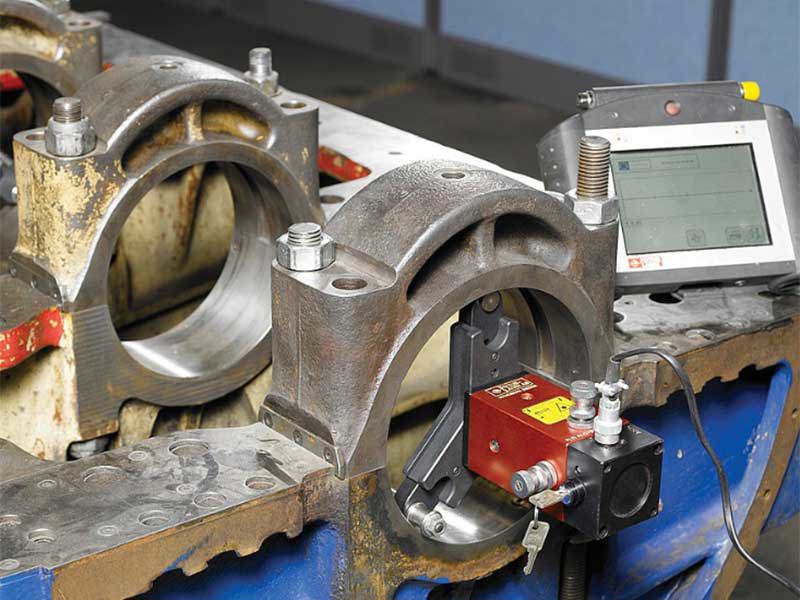

One of the primary reasons to choose Metalock Engineering for your engine alignment needs is the technology we use. We use state-of-the-art laser alignment equipment that enables us to perform measurements and corrections with complete precision. We can make sure that all your engine components are perfectly aligned, which will maximise the efficiency of your critical machinery and reduce mechanical stress.

Why Choose Us?

There are many reasons to choose Metalock Engineering for your engine alignment needs. These include:

Expertise

You need to know you are in safe and experienced hands when it comes to a service as important as engine alignment. Metalock Engineering is a global leader in industrial equipment maintenance and repairs with extensive experience in engine alignment services. We have provided this service for businesses in many industries and in challenging work environments, so you can rest assured that our highly trained technicians will be able to complete the work quickly, efficiently, and safely.

24/7 Support

We have a 24/7 support service, and you can contact us any day of the year. We understand that alignment needs must be addressed promptly, so we pride ourselves on our rapid response time.

Global Presence

We also serve over 100 countries and have our highly skilled technicians located all around the world and ready to travel at short notice. This allows us to respond to your alignment needs quickly so that you can avoid the dangers and costs associated with misalignment.

Contact Metalock Engineering Today for Engine Alignment Services

Engine alignment is a vital maintenance service for businesses in wide-ranging industries. Misaligned components can lead to expensive repairs, operational disruption, and downtime. This is why engine alignment should be conducted on a regular basis to ensure that the internal components are precisely aligned for optimal performance and efficiency.

As such an important maintenance task, it is important that you have an engine alignment specialist that you can trust. Metalock Engineering is a global leader in specialist engineering for every industry, and we have extensive experience in engine alignment using our advanced technologies and techniques to ensure precise alignment of engine components.