We have expertise in medium, large and very large in situ crankshaft repairs. We can address a wide range of common crankshaft issues and carry out the work on-site, helping you to avoid costly downtime and loss of revenue.

The crankshaft is a critical engine component but also one that is subjected to high levels of stress and wear because of continuous motion and heavy forces.

Engines are used in all industries throughout the world.

Marine/Offshore: ships, rigs and offshore installations all use large diesel engines as a means of either propulsion or power generation.

Industries such as mining, power generation, landfill gas, petrochemical, construction all use diesels engines to power plant and machinery. They are even used as a source of standby power generation for banks, hospitals and many are used to power our trains and large industrial vehicles.

Common Crankshaft Issues

There are several issues that can arise with crankshafts and crankshaft failure can happen at any time, even on well-maintained engines. Crankshaft issues are problematic because they can prevent the engine from working efficiently and if not corrected can cause total engine failure. This can lead to expensive repairs/replacements and downtime. This is why crankshaft repairs must be carried out as quickly as possible to prevent loss of revenue. A few of the most common issues that we deal with at Metalock Engineering include:

Bearing failure: Bearings can become worn over time, which can result is catastrophic engine failure.

Cracks and fractures: Cracks and fractures can occur from fatigue and continuous stress.

Corrosion and pitting: Corrosion and pitting can occur on the crankshaft journal diameter surface.

Bearing Journal Ovality: Crankshaft journals can become out-of-round from wear and tear, which can cause uneven distribution of forces and damage the engine.

Cam Effect or ridge wear: This condition develops over a period of time and can be identified as a protruding band that goes around the circumference of the crankpin journal diameter, The effect can cause extensive build up of heat which can harden the crankpin diameter causing problems in lubrication and eventual crankpin bearing failure sometimes causing disastrous results.

Crankshaft Repairs From Metalock Engineering

Here at Metalock Engineering, we understand the importance of timely, reliable, and precise crankshaft repairs. Every crankshaft repair project is unique, so we take the time to understand the specific requirements so that the best repair technique can be employed. We can also carry out repairs on land, at dock, or even mid-ocean.

Our comprehensive on-site service comprises of the following

- NDT Inspection Pre/Post Machining.

- Hardness Inspection Pre/Post Machining.

- Machining of Crankpin Journal diameter.

- Machining of Fillet Radii

- Final Polishing of Crankpin Journal.

- Provide full Pre/Post Machining Dimensional Report.

- Heat treatment to reduce hardness values (if required)

- Crankshaft straightening (if required)

Why Choose Metalock Engineering for Crankshaft Repairs?

There are many good reasons to choose Metalock Engineering for your crankshaft repair needs. In addition to over 70 years of experience in specialist repairs, serving businesses around the world and in many industries, we are the largest on-site machining group in the world. Here are a few of the key benefits of using Metalock Engineering for crankshaft repairs

Class Approved

We have a Lloyds accreditation for the “In-Situ” annealing and re-machining of crankshafts installed in marine or land-based diesel engines.

24/7 Crankshaft Repairs

One of the main reasons to use Metalock Engineering for your crankshaft repair needs is the fact we offer a 24/7 repair service. You can call us at any time, any day of the year, and we will be ready to provide support. This means that we can respond quickly to your needs, helping to keep downtime to a minimum.

Global Response

We also have our team of skilled technicians strategically placed around the world, meaning we can deploy the person closest to you. Again, this can help minimise downtime and can get you fully operational again before long.

On-site Repairs

In addition to 24/7 global response service, we can carry out crankshaft repairs on-site. This is important because it means that you do not have the cost and logistics of taking the engine apart and sending components away for repairs. This can save you a lot of money and keep downtime to a minimum.

Extend Engine Service Life

Thanks to our advanced crankshaft repair techniques and highly skilled technicians, we can often restore the crankshaft to full working condition in line with the original manufacturer's specification. This can extend the engine service life and help you avoid the costs involved in premature engine replacement.

If you ever experience crankshaft issues or failure, do not hesitate to reach out to Metalock Engineering for crankshaft repairs. Metalock makes sense as your crankshaft repair provider every time, as we can keep downtime to a minimum and help you avoid untimely replacement costs. You know you are in safe hands with Metalock Engineering.

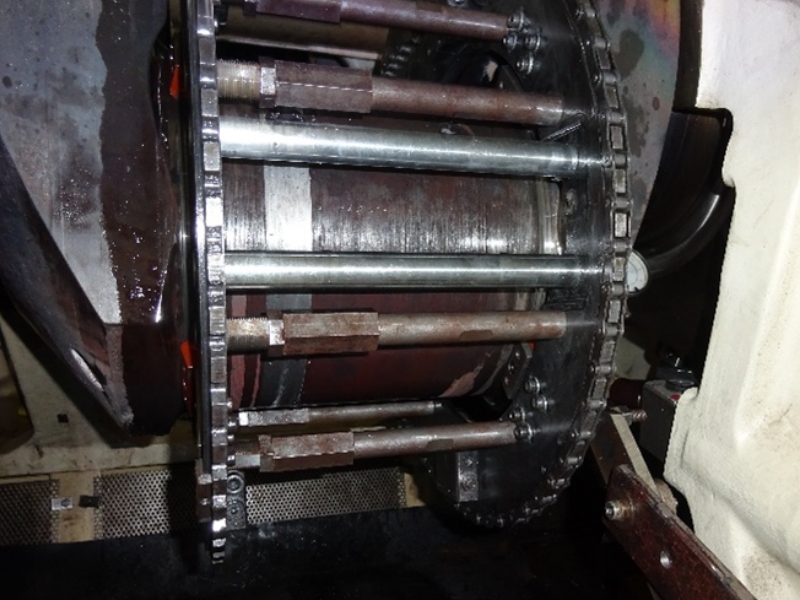

Crankpin at top dead centre

Crankpin at top dead centre Crankpin at bottom dead centre

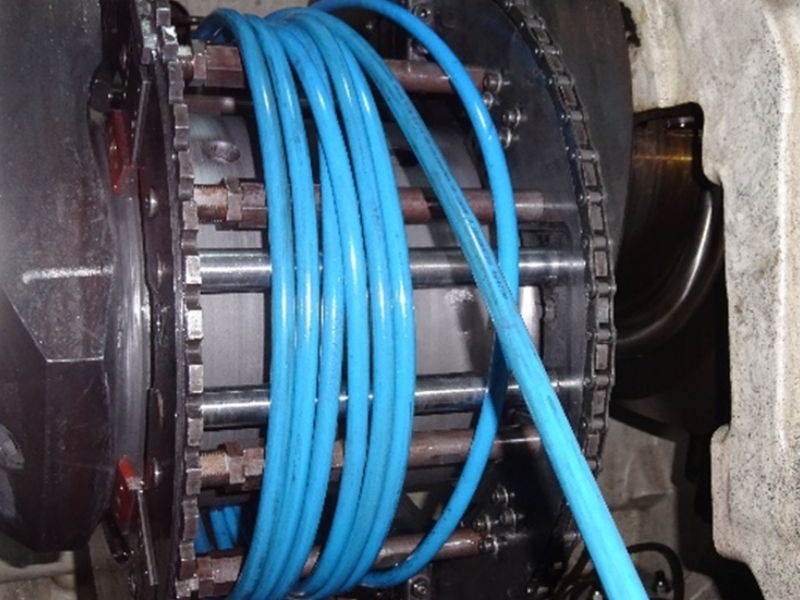

Crankpin at bottom dead centre In situ Heat treatment

In situ Heat treatment Re-machining the bearing journal

Re-machining the bearing journal Superfinishing the bearing journal

Superfinishing the bearing journal All work and inspection complete

All work and inspection complete