One area that we specialize in is heritage steam engine repairs. We can carry out steam engine repairs covering a wide range of issues, helping you to get your steam engine fully operational again before long

The steam engine was invented by Richard Arkwright in 1786 first used in the cotton mills to drive all of the looms. Then adapted as steam engines for rail travel and steam turbines for power generation and ship propulsion.

It’s not a green energy because lots of power stations burn coal to generate steam.

How Steam Engines Work

As with any type of engine, there are many components that make up a steam engine. Essentially, steam engines work by converting thermal energy from steam into mechanical work.

This involves water being heated in a boiler to produce steam, which then builds up to create pressure in the boiler. This high-pressure steam is then introduced into a cylinder, which pushes a piston. The movement of the piston converts energy from steam into mechanical motion. The steam is then exhausted from the cylinder to a condenser or into the atmosphere.

A crankshaft is also used to convert the linear motion of the piston into rotational motion, which allows for the turning of wheels and other tasks.

Common Issues

As a complex piece of equipment, there are a number of issues that can arise within a steam engine that can impact its performance and stop it from working entirely. Here are a few of the common issues we see at Metalock Engineering:

- Boiler issues: Boiler issues can include scaling, corrosion, and explosions due to excessive pressure.

- Steam leakage: Worn seals and gaskets can cause steam to leak and impact the performance of the steam engine.

- Mechanical wear and tear: As with all types of engines, wear and tear can occur over time from continuous movement. This can include pistons, cylinders, bearings, and crankshafts.

- Condensation issues: Pipes and cylinders can become damaged from the sudden condensation of steam, which causes a rapid increase in pressure.

Fuel inefficiency can occur when incomplete combustion wastes fuel and produces excessive smoke and pollutants.

These are a few of the most common issues we see with steam engines, but there are others. Regular maintenance and inspections will be key to preventing these issues from arising, but if you notice a problem with your steam engine, it is important to contact a specialist to ensure that repairs are carried out safely and to the highest standard.

Metalock's Steam Engine Repair Service

Metalock Engineering can carry out a wide range of steam engine repairs to get your engine fully operational once again. Our advanced technology and skilled technicians can provide a range of solutions, including:

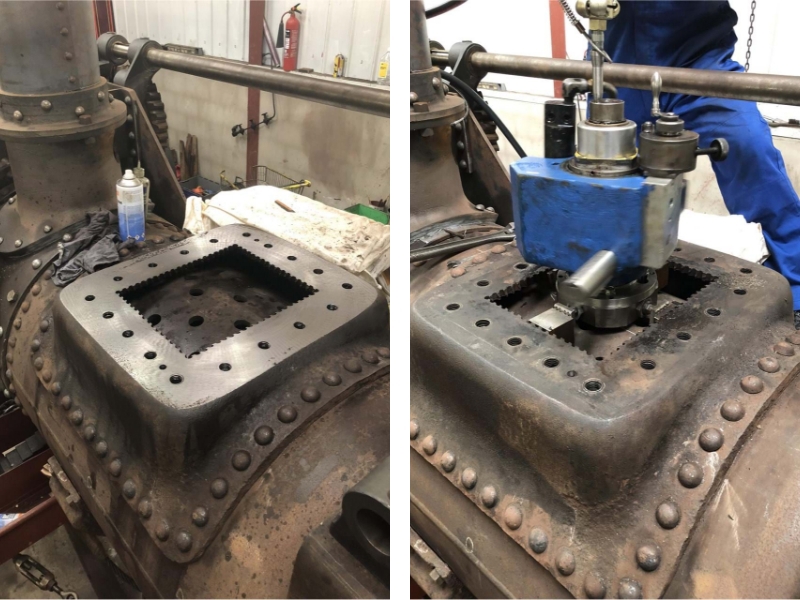

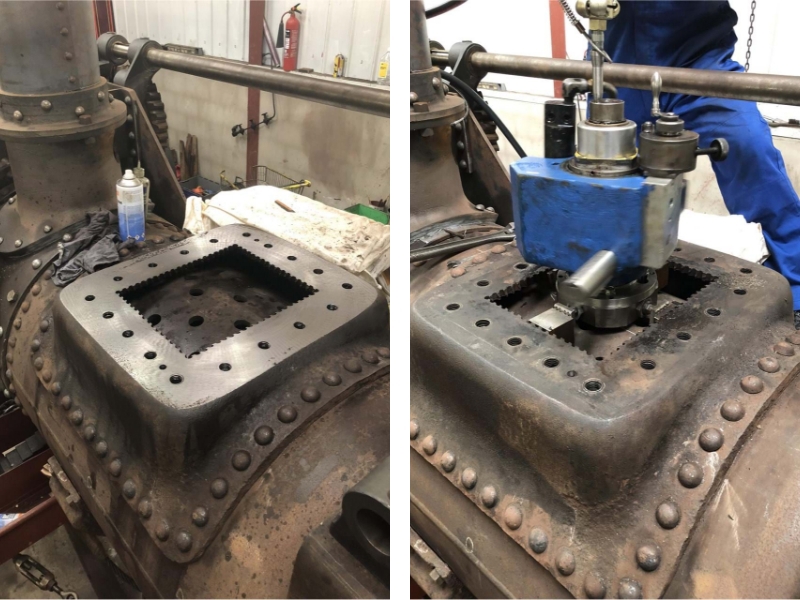

- On-site machining: One key benefit of using Metalock Engineering for your steam engine repair needs is our on-site machining capabilities. Our tools and techniques mean that repairs can often be carried out on-site, which prevents the need to disassemble the steam engine and send away parts for repair—a logistical and expensive challenge.

- Metrology: Alignment is key for steam engines, so laser tracking and 3D scanning technologies can be used to ensure the precise alignment of key components.

- Thermal spraying and coating: Thermal spraying techniques can be used to apply protective coatings against corrosion and general wear. This can extend the lifespan of components and restore their surface integrity.

- Valve and cylinder repairs: We can also repair steam engine valves and cylinders, which can involve machining valve seats and re-boring cylinders to create tight seals and maintain the steam engine's performance and efficiency.

Why Use Metalock Engineering?

So, why should you choose Metalock Engineering for your steam engine repair needs? In addition to being the largest on-site machining engineering group in the entire world with over 120 years worth of experience in specialist engineering, we also offer a 24/7 worldwide response service.

We have a team of skilled technicians positioned all over the world who are ready to travel at a moment's notice. This means that they will be well-positioned and able to reach you quickly once you have made an inquiry. On-site repairs will get you fully operational again before long and help keep your repair costs down.

No matter what industry you are operating in or the working conditions, our technicians will be able to get to work and get your equipment working again as quickly as possible. This prevents downtime and will help you protect your reputation.

Get In Touch Today To Learn More

Steam engines were once the cornerstone of industrial machinery since the 1800s and were used in many different settings. While steam engines can be an effective piece of machinery, there is also a lot that can go wrong. Issues with a steam engine can cause inefficiencies and stop the engine from working entirely, leading to expensive downtime.

This is why you need to turn to a company with expertise in steam engine repairs that will be able to travel to your location and carry out repairs on-site without the need to take the entire engine apart and send away components for repairs.

Metalock Engineering has extensive experience in heritage steam engine repairs and is available 24/7, 365, with technicians located all around the world. This means we are well-positioned to reach you and can get to work quickly.