With over 70 years worth of experience and serving over 100 countries, you know you are in safe hands with Metalock Engineering. We conduct repairs on a huge range of components, including hydraulic press repair. We can restore your hydraulic press with our advanced repair techniques that will keep downtime to a minimum. Keep reading to find out more.

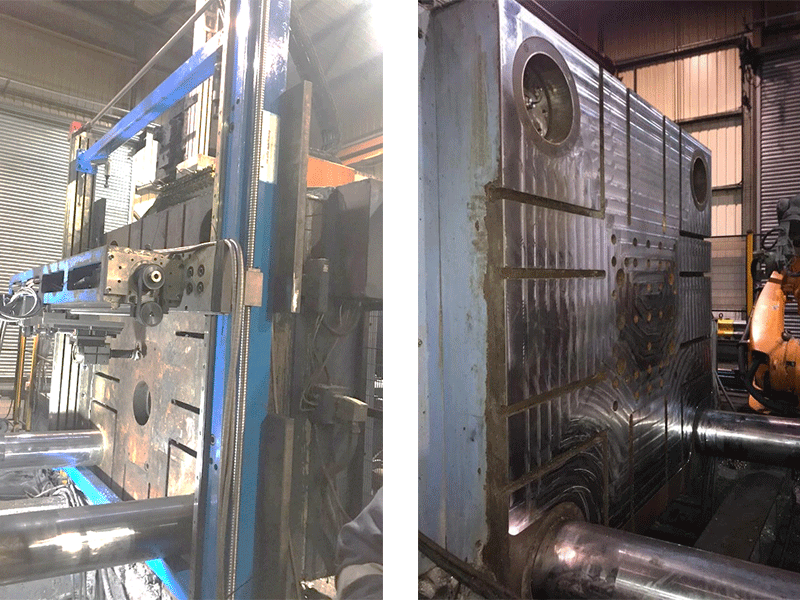

Machining face of an Injection Moulding Press Platen

What is a Hydraulic Press?

A hydraulic press is a machine that generates force via hydraulic pressure for compressing, holding, or shaping materials. It is a complex machine utilising a hydraulic system, pistons, cylinders, and a frame that is capable of withstanding enormous pressure.

Hydraulic presses are used in a number of different industries and can be used for many key processes, including metal forming and plastic moulding. This makes them an integral piece of equipment, but there are a number of issues that can arise that can impact the performance of the press and bring operations to a grinding halt.

Industries That Use Hydraulic Presses

As mentioned, hydraulic presses are commonly used in a number of different industries. Here are a few where they are typically found and their uses:

Automotive: Hydraulic presses are used in the automotive industry for stamping, forming, and assembling various parts, including panels and gears.

Aerospace: Hydraulic presses are also used in aerospace for the precise forming of high-strength materials used for aircrafts and spacecrafts.

General Manufacturing: Hydraulic presses are widely used in manufacturing. They are used to both assemble and disassemble components that fit tightly together.

Metal Fabrication: In metal fabrication, hydraulic presses are used to form and shape sheets, plates, and components for industrial applications.

Food and Beverage: in the production of food and drinks cans

Common Issues With Hydraulic Presses

As a complex piece of equipment with many components and often operating continuously in challenging environments, there are a few common issues that can damage a hydraulic press and stop it from working efficiently. These include:

Cylinder and piston wear: One of the most common issues is cylinder and piston wear. This occurs simply from continuous operation over time, which can lead to reduced force and impact the performance of the press.

Frame cracks: The hydraulic press frame is built to withstand immense pressure, but structural cracks can occur, which compromise the stability and alignment of the press.

Hydraulic system failures: There are various issues that can lead to a drop in hydraulic pressure, including leaking seals and damaged valves. This can affect the efficiency of the press.

Electrical issues: There are also various electrical issues, such as faulty wiring and sensors, which can result in a complete shutdown of the press.

Hydraulic Press Repair Services

If you notice that your hydraulic press is not working as expected, it is important that you get it repaired as quickly as possible. Here at Metalock Engineering, we have experience in repairing hydraulic presses in various industries. With our advanced repair techniques, we can get you fully operational again before long and restore your hydraulic press to its original manufacturer specification, all while minimising disruption to your operation. Here are a few of the main reasons why you should contact us for your hydraulic press repair needs:

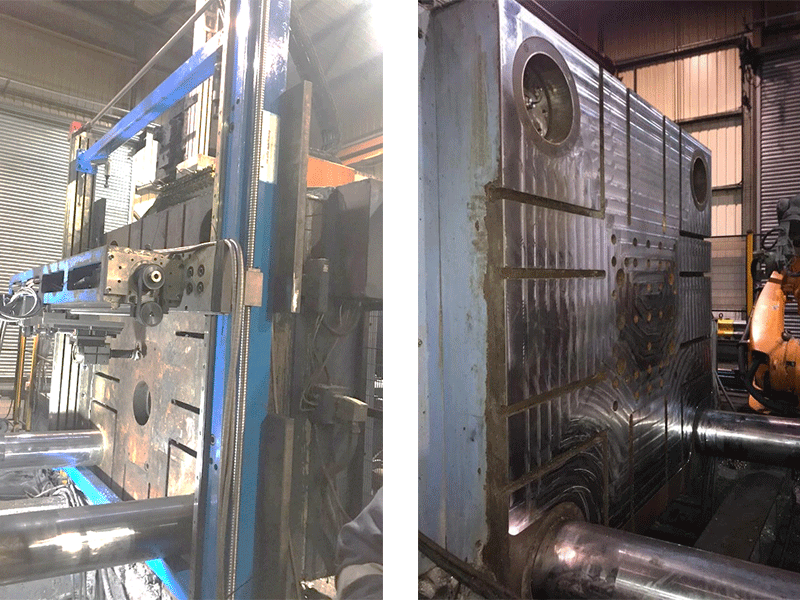

CNC machining of central pressure pad on the face of a 3000T Extrusion Press

CNC machining of central pressure pad on the face of a 3000T Extrusion Press

Advanced Repair Techniques

First, we have developed advanced repair techniques that can restore your hydraulic press quickly and to the highest standard. We can utilise many advanced repair techniques, such as our patented

Metal stitching technique for fixing cracked press frames

Cold Metalock casting repairs on cracked press die for the automotive industry

Precision in situ machining to re-grind press beds machining new T slots

Canning Press regrind.

Laser Tracker Alignment for accurate press frame inspection surveys

Specialist Welding services

On-Site Repairs

One of the major advantages of choosing Metalock Engineering for your hydraulic press repair needs is the fact that we can often carry out our repairs on-site. We can send a technician to you, which prevents the need for you to send the press away for repair - this can speed up the repair time as well as save you money. Our technicians are skilled and experienced in working in different environments, so they will be able to keep disruption to a minimum.

Cost-Effective Repairs

You can often save money by opting for our hydraulic repair services. This is because it can be cheaper than buying a new hydraulic press, and we can keep downtime to a minimum by carrying out repairs in situ.

Global Presence

We serve over 100 countries (and counting) and have headquarters in countries all around the world. Our repair technicians are strategically located and ready to travel at short notice, so we can deploy a technician near you so that the repair can be carried out as quickly as possible.

24/7 Support

You can contact Metalock Engineering 24/7 and 365. We know that repairs need to be completed as quickly as possible to avoid costly delays, so we make ourselves available 24/7 and will respond to your emergency as quickly as possible.

Commitment to Safety

It is important that the repair is carried out quickly, but we always prioritise safety. Our technicians are highly trained and have a strong sense of safety awareness, so repairs will always be carried out safely, and your equipment will be safe to use afterward.

Contact Metalock Engineering for Hydraulic Press Repairs

If your hydraulic press is not working properly or at all, we are here to help. We have expertise in hydraulic press repairs and use advanced repair techniques that can restore your hydraulic press. We can often carry out the repairs in situ, which can help keep downtime to a minimum while saving you the hassle of sending the press away for repair.

CNC machining of central pressure pad on the face of a 3000T Extrusion Press

CNC machining of central pressure pad on the face of a 3000T Extrusion Press