Metalock Engineering provide specialist hydro turbine repair services in support of OEMs and hydro turbine operators on a global basis.

How do Hydro Turbines Work?

Hydro turbines are a remarkable form of renewable energy that is poised to gain even more traction in the future. They operate by directing water towards the turbine, with the potential energy of the stored water converted into kinetic energy as it flows towards the turbine. The turbine’s blades start spinning when the water strikes them, causing the blades to rotate a turbine shaft turning mechanical energy to the coupled generator shaft as part of the generator rotor. This in turn generates electricity sending it to the power grid network.

Power Generation:

Obviously, hydro turbine/generators have been generating clean power for well over 100 years. The first was a very small unit at Cragside Hall in Northumberland England in 1878. The first hydroelectric power plant was built in Wisconsin and became operational in 1881. It was called the Fox River Plant and was developed by inventor and engineer Thomas Edison. The plant used the power of the Fox River to generate electricity for the local area.

Currently hydroelectric power plants use hydro turbines to generate electricity that can be used for residential, commercial, and industrial use. These plants are operated by major utility and energy companies throughout the world.

Hydro Turbine Problems

As you might imagine, things can go wrong with hydro turbines and problems with a hydro turbine can stop the production of electricity and lead to costly outages and repairs.

Erosion & Corrosion: Turbine components can become worn over time due to constant exposure to the abrasive action of particles in water. Corrosion can also occur from reactions with water and other substances.

Cavitation: Damage to the blades and other components can arise from cavitation, which occurs when bubbles form in the water as it flows over the turbine blades.

Vibrations: Excessive vibration can cause mechanical failure and reduced efficiency. This can result from imbalances, misalignment of the turbine shaft, or operational issues.

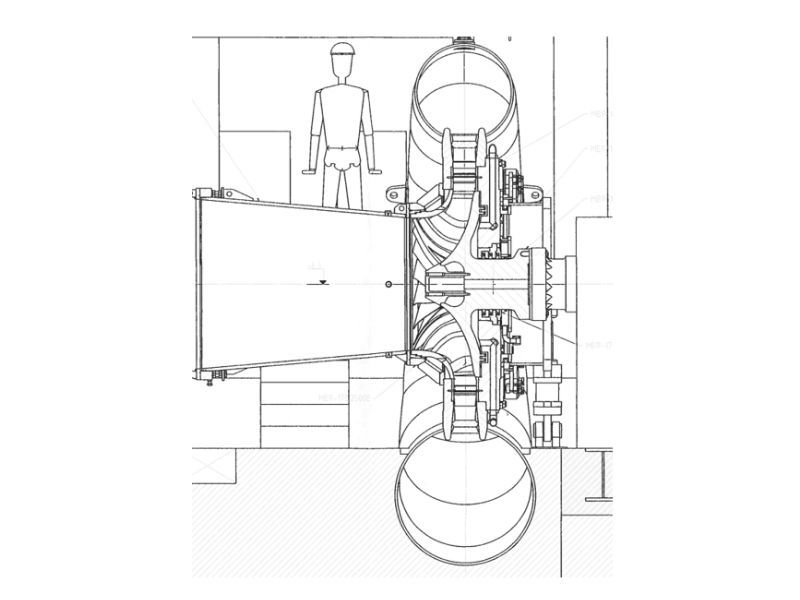

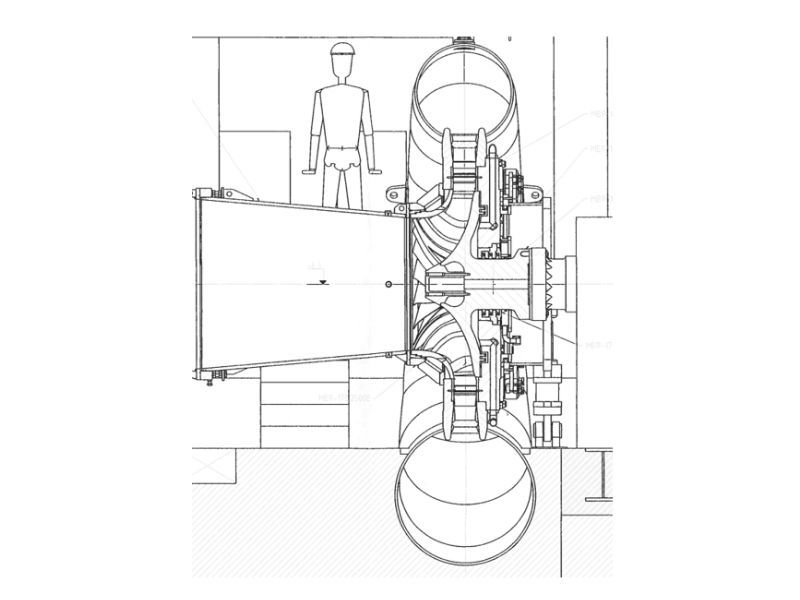

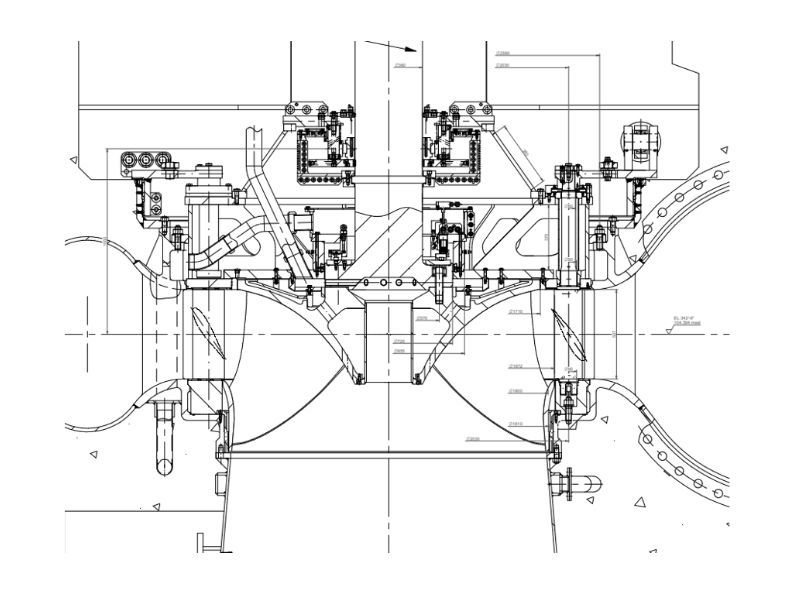

Horizontal Unit

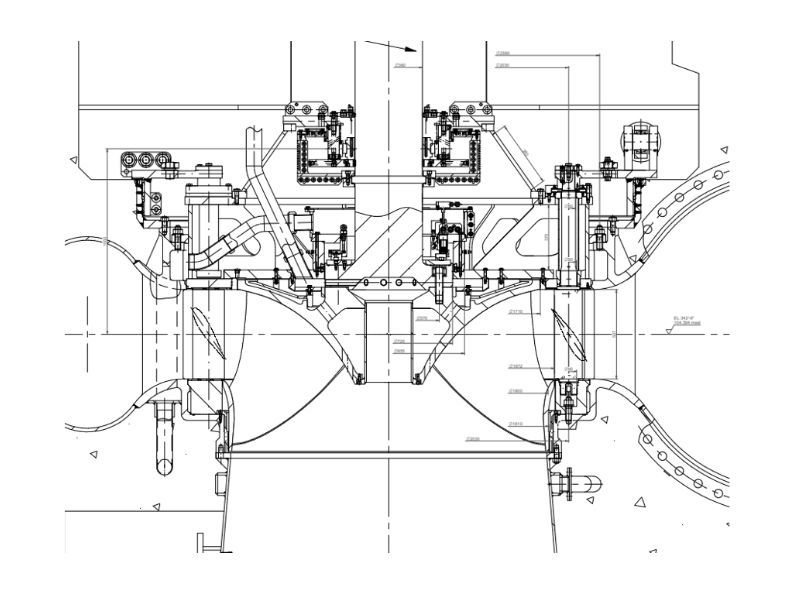

Vertical Unit

Hydro Turbine Repair Services from Metalock Engineering

You can turn to Metalock Engineering to supply specialist engineering services that will support your hydro turbine repair and overhaul needs. Problems with a hydro turbine can lead to costly downtime and production losses. Metalock Engineering have extensive experience in hydro turbine repair projects all around the world.

Global 24/7 Response Service

One of the main reasons to choose Metalock Engineering for your hydro turbine repair needs is the fact that we offer a global 24/7 response service. We have technicians located strategically around the world ready to be deployed at a moment’s notice, so when we get the call, it should not take long for us to reach you. Additionally, we have a 24/7 emergency response service, meaning that you can call us at any time, and we are ready to help.

Metalock Engineering can offer the following engineering services to assist on your project

In-Situ Machining

Metalock Engineering can provide in-situ boring, facing, milling, drilling and tapping This means that machining repairs can usually be carried out on-site preventing the need for expensive strip-down and transportation costs.

Milling generator slots

Re-profiling draft tube

Machining Main Inlet valve faces

Laser Tracker and Scanning services

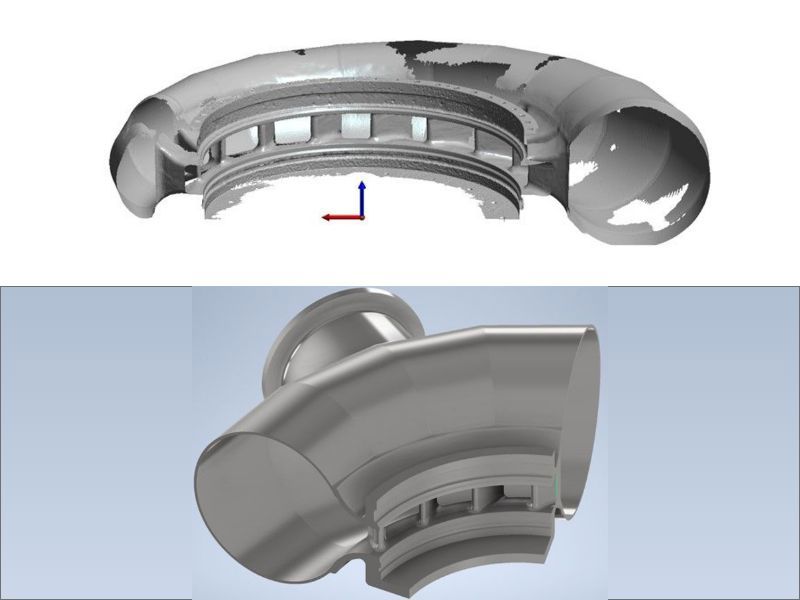

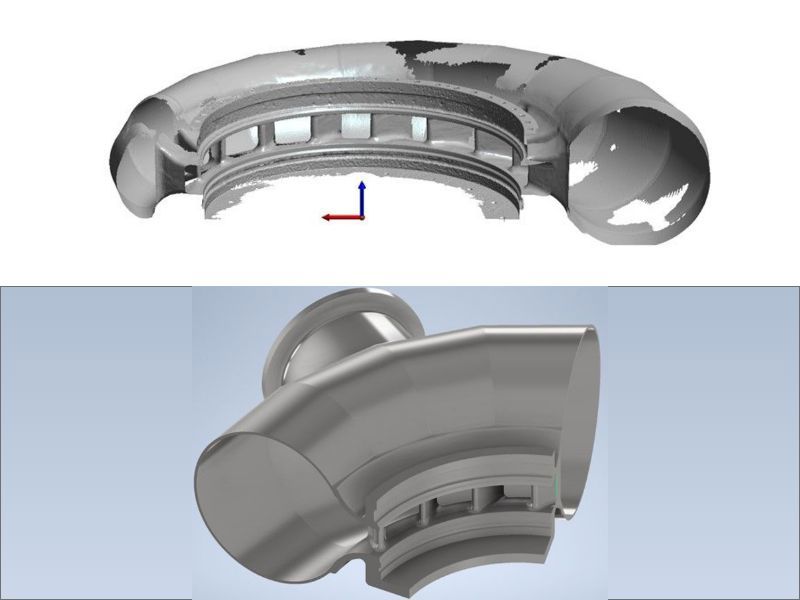

Laser Tracking surveys record accurate laser measurements to establish the alignment and condition of the spiral casing and draft tube. This highlights any areas that are worn or out of alignment. We can the used that data to produce a 3Dscan of the Unit and produce engineering drawings.

3D Scanning Spiral casing

Metalock Cold Casting Repair Services

Experienced Team

Obviously, you need to know that your hydro turbine repairs are being carried out by qualified and experienced engineers. At Metalock Engineering, we have a team of highly experienced engineers who have worked with on power generation project all around the world working with OEMs, and operators to assist with turbine repairs and upgrade modifications. This means that our team is experienced and confident in working in various industrial environments and knows how to get the job done while minimizing disruption.

Contact Us For Your Hydro Turbine Repair Needs

As you can see, Metalock Engineering is the logical choice when it comes to hydro turbine repairs. Hydro turbines are a terrific form of renewable energy and play a big role in sustainability efforts in the years to come, but they are not fool-proof. There are a number of problems that can arise with hydro turbines that can cost a huge amount in terms of downtime, lost production, and replacement/repair costs.