Using our advanced repair techniques, we can restore your kiln tyre to its original specification and keep downtime to a minimum with our on-site repair services. Interested? Read on to find out more about our kiln tyre crack repair service.

What are Kiln Tyres?

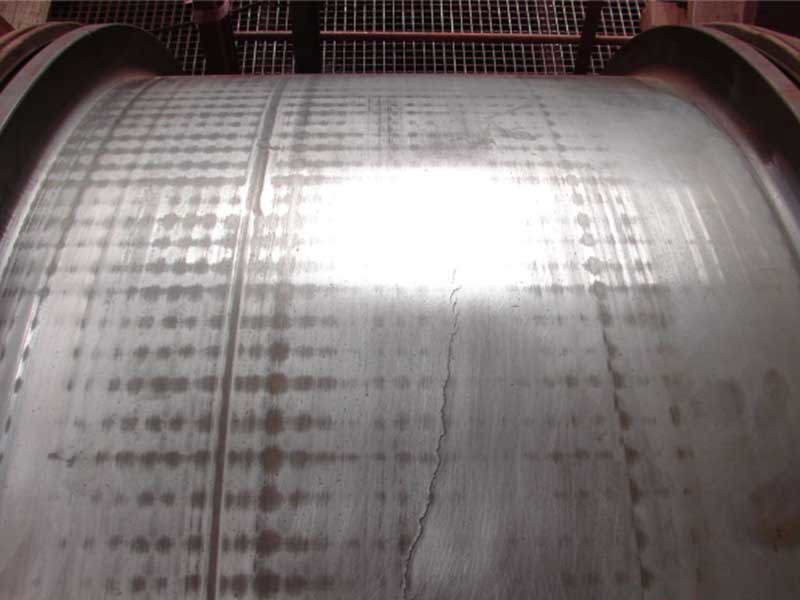

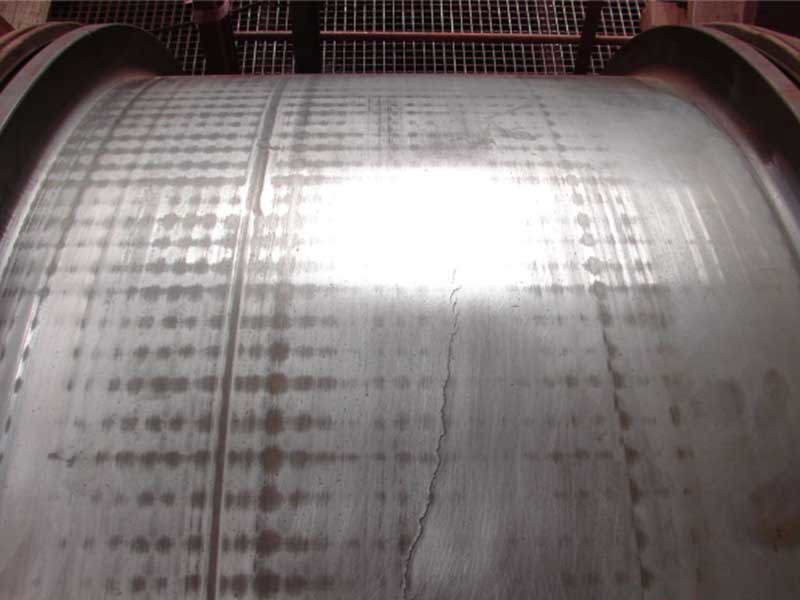

So, what exactly are kiln tyres? A rotary kiln tyre, also known as a rolling ring or support ring, is a circular component that supports the rotary kiln shell. A rotary kiln is a cylindrical furnace that rotates slowly while heating materials to a high temperature. The kiln tyre plays a key role in facilitating uniform rotation, weight distribution, and maintaining structural integrity.

Due to the nature of the operation, kiln tyres are designed to withstand extreme heat, wear, and mechanical stress and are used in challenging and harsh environments. Inevitably, this means that there are issues that can occur with kiln tyres over time, and cracks can be a significant issue.

Industries That Use Kiln Tyres

Kiln tyres are used in a number of industries that use rotary kilns as part of their production process. This includes:

Chemical & Petrochemical: Rotary kilns are used in chemical and petrochemical applications, with kiln tyres being used to withstand high temperatures and corrosive environments.

Cement & Lime Production: Rotary kilns are also used for the production of cement and lime. Kiln tyres are used to maintain the stability of the production processes.

Mining & Metals: Rotary kilns are used to roast ores and other materials in mining and metallurgical industries, with kiln tyres used to provide structural integrity.

Waste Processing & Recycling: Rotary kilns are also used in waste processing and recycling for incineration, recycling, and waste processing.

Common Causes Of Kiln Tyre Cracks

Cracks are one of the most common problems with rotary kilns and are a serious issue that can bring the operation to a grinding halt. A few of the most common causes of kiln tyre cracks include:

Thermal Stress: Extremely high temperatures are used, and repeated heating and cooling cycles can cause thermal stress, leading to cracks in the kiln tyre.

Wear & Erosion: Kiln tyres must be properly maintained to prevent wear and erosion. Without this, the tyre becomes weaker and will be more likely to crack.

Overloading: Cracks and fractures can occur from excessive weight or uneven load distribution.

Misalignment: Improper alignment between the tyre and shell creates uneven pressure and stress points that can lead to cracks.

External Damage: Debris and physical impact can occasionally cause cracks to the kiln tyre during operation or create stress concentrations that lead to the formation of a crack.

Kiln Tyre Crack Repair Services from Metalock Engineering

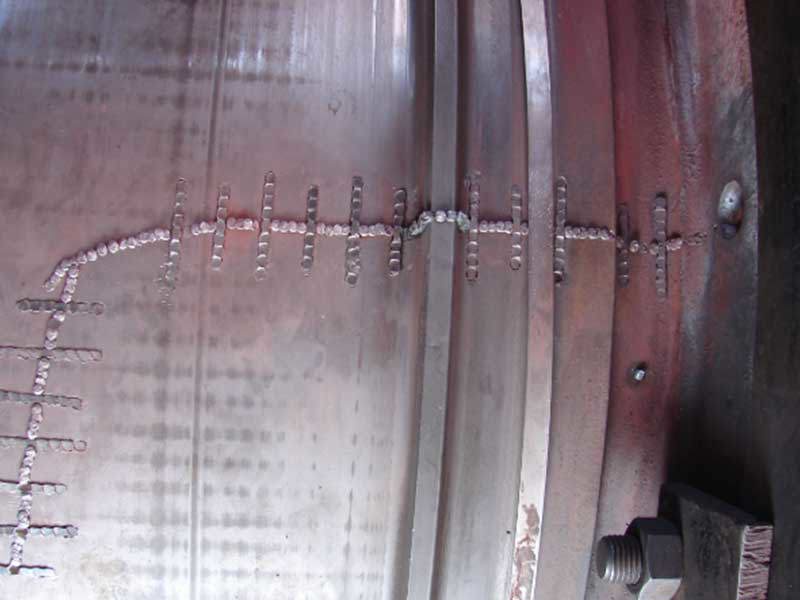

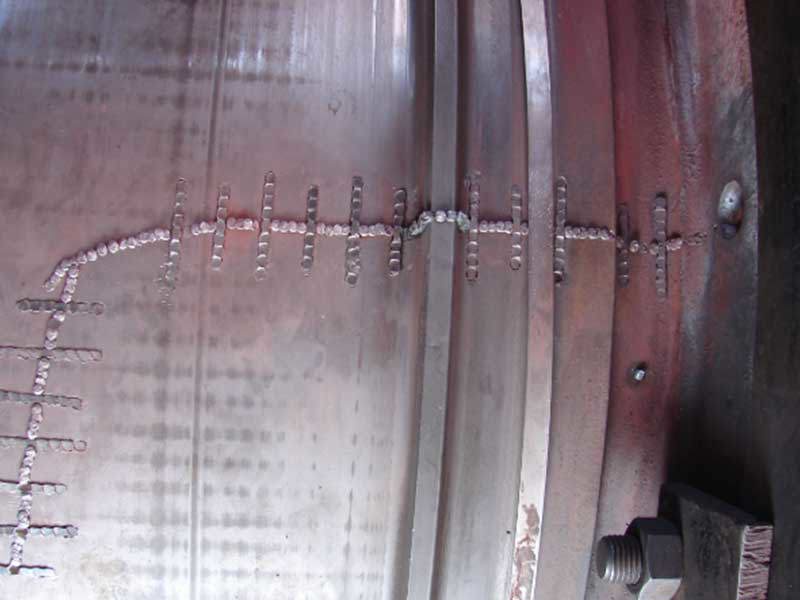

If you have a crack in your kiln tyre, you need to get it repaired as soon as possible. Here at Metalock Engineering, we have extensive experience repairing kiln tyre cracks and can restore your equipment to its original specification.

We have a few techniques that can be used to restore your kiln tyre and get you operational again before long. This includes our trademark metal stitching technique, which involves creating tailored "keys" to fix the crack. This is a cold repair technique, which can prevent distortion and further damage - this is always a risk when using welding.

We can also repair cracks with our surface restoration and corrosion repair and prevention techniques. In addition to this, we provide on-site machining and alignment that can correct any issues with the alignment for smooth and safe rotation.

Why Choose Metalock Engineering for Kiln Tyre Crack Repairs

We are confident that we are the best repair partner for your kiln tyre crack repair needs. Here are a few of the main reasons why:

On-site Repairs

Unlike many other repair companies, we can usually carry out kiln tyre crack repairs on-site. Our advanced repair techniques allow us to carry out repairs in situ, which prevents the cost and logistical challenges involved in sending components away for repair. Carrying out repairs on-site also means that the work is completed much faster, helping to keep the costs of downtime to a minimum.

24/7 Availability

We understand that repairs to critical industry equipment need to be completed as quickly as possible to prevent downtime. This is why we make ourselves available 24/7, 365. No matter when you need us, we will be there to support you and get you fully operational again before long, even on Christmas Day!

Global Response Service

We also have a global response service. We serve over 100 countries worldwide and counting, and our highly skilled technicians are located around the globe. They are ready to travel at short notice, so we can send someone to you and they will arrive to carry out the repair before long.

Cost-Effective

Choosing Metalock for your kiln tyre crack repair needs is smart from a financial standpoint. Repairing the crack is often much more affordable than replacing the kiln tyre, plus we are able to keep downtime to a minimum which will help you make further savings.

Trusted Repair Specialist

Finally, you know you are in safe hands when you choose Metalock Engineering. We have over 120 years of experience in industrial component repair and have a strong reputation for our advanced and patented repair techniques and technologies.

Contact Metalock Engineering Today For Kiln Tyre Repair Services

All of our technicians are trained to the highest standard and are capable of carrying out repairs quickly, efficiently, and safely. This can provide peace of mind, knowing that you are using an expert repair specialist.