We have over 75 years of experience in specialist cold casting repairs on cast iron, cast steel and cast aluminium. Keep reading all you need to know about our innovative approach to repairing cast iron components and how we can get production up and running again before long.

What is a Metalock repair (Metal Stitching)?

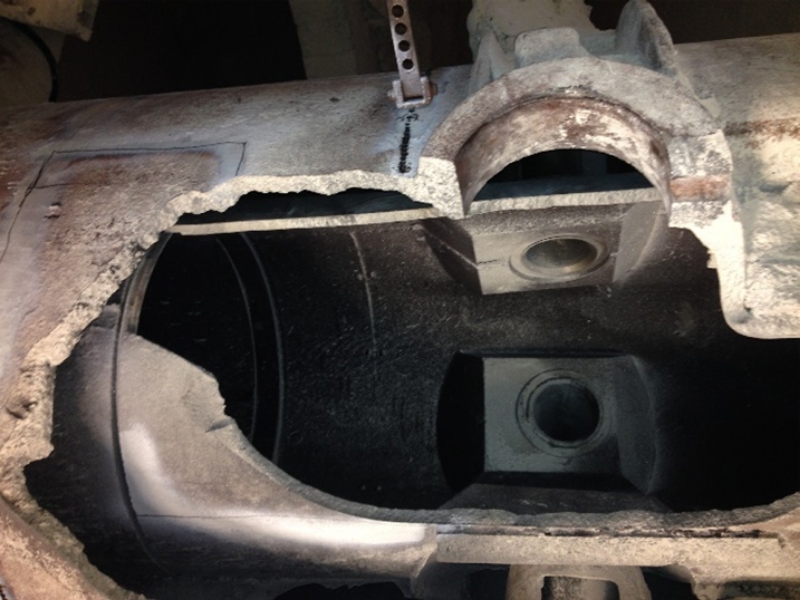

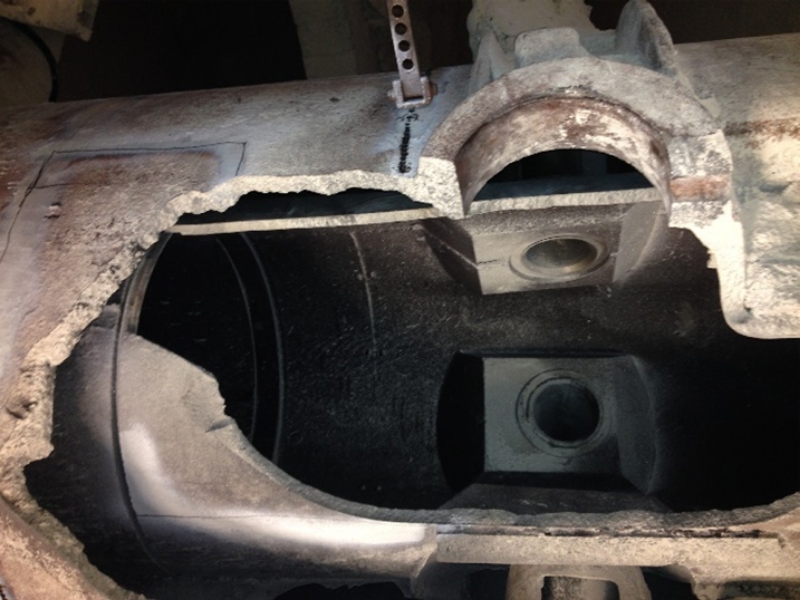

So, what exactly is a Metalock repair (also referred to as Metal stitching), this is a simple yet highly effective way to repair cracks in cast iron components without the need for welding. This is a cold repair technique, which is important because applying heat via welding can sometimes cause further damage to the component.

The metal stitching process involves creating and inserting tailor-made metal alloy locks (or keys) into the pre-machined holes along the crack. These locks can hold the material together and restore structural integrity, which means that the original shape and alignment are maintained. Metal stitching can be a highly effective solution to cast iron repairs and can be used in wide-ranging industries.

The metal stitching process dates back over 70 years. The team developed special tools, jigs, fixtures, and materials that allowed them to successfully cold repair all kinds of equipment and restore heritage structures.

The Benefits of Metal Stitching from Metalock Engineering

There are a number of reasons why metal stitching is the best repair technique when it comes to cast iron components repairs. The main benefits include:

Heat-Free

One of the main benefits of metal stitching is it is a heat-free repair. Cold repairs are beneficial when it comes to cast iron repairs as they can prevent warping and damaging the structural integrity of the component, which is always a risk when it comes to welding.

On-Site Repairs

Another reason to opt for Metalock’s metal stitching for cast iron repairs is the fact that we can carry out repairs on-site. Our trained Metalock repair technicians can come to you to carry out the repair, which can help you avoid the cost and logistics of sending cast iron components away for repair.

Minimise Downtime

Metal stitching and on-site repairs can also be carried out quickly, which can help minimise downtime. Downtime can cost industrial businesses a fortune and damage their reputation, so you want to make sure that cast iron repairs are completed as quickly as possible.

Durability

Metal stitching is a durable repair technique that can restore the structural integrity of your cast iron components. This means that your equipment will perform to a high level and last the test of time.

Cost-Effective

Metal stitching can also be cost-effective. It can be a lot more affordable to use this repair technique than having to replace cast iron components, helping you save money over the long term.

Global & 24/7 Response

Another reason to choose Metalock Engineering for your cast iron repairs is the fact that we offer a global and 24/7 response service. We serve over 100 countries around the world and have a team of highly skilled technicians strategically placed and ready to travel at short notice. You can contact us 24/7, 365, and we will be able to send someone out to you quickly, helping you get fully operational again before long.

Internationally Recognised

The Metalock metal stitching repair technique is one that is globally recognized, and has been tested and is approved by Lloyds Approved and Bureau Veritas. This means that you can rest assured knowing that this is a technique that is proven, safe, and reliable.

Common Issues that require Metal Stitching

There are a few common issues that can occur with cast iron components that can benefit from metal stitching. Generally, these occur when cast iron components are used extensively over time and/or exposed to harmful environments. Breakages usually occur because of overloading, accidents, equipment misuse or flaws in the casting.

Wear and tear: Wear and tear is the most common issue with cast iron components. This is a result of continuous operation and friction, which can result in damage to the surface of the component.

Cracks and fractures: Cast iron is an incredibly durable material, but cracks and fractures can develop. This is often a result of thermal stress, mechanical overload, or operational fatigue. These cracks can quickly grow and destroy the component, which is why timely repairs are key.

Corrosion: Cast iron components are often exposed to harsh environments, chemicals, and moisture. This can cause damage to the cast iron component surface, which can then be restored with the use of metal stitching.

Industries Where Metal Stitching Can Be Used

Metalock Engineering has experience in carrying out metal stitching repairs in all industries and for many different applications. A few of the main industries we have experience serving include:

- Marine and Offshore

- Steel

- Mining, mineral, cement, and aggregates

- Naval

- Petrochemical

- Power plant

- Pressing and forging

- Heritage

- Paper

- Manufacturing

- Automotive

- Food and Beverage

- Rail

In Need of Cast Iron Repairs? Get in Touch Today

If your cast iron components are damaged, it is important that you get them repaired as quickly as possible. Get in touch with our team today, and we will be able to send someone to you to carry out the repair in-situ. This can help keep downtime to a minimum, get you up and running again, and prolong the life of your industrial equipment.

At Metalock Engineering, we understand the importance of timely yet precise and high-quality repairs. We have over 70 years of experience in specialist engineering for every industry, so we are confident that we are the smart choice for your cast iron component repair needs. Using our patented and proven metal stitching technique, we can restore your cast iron components and get your production up and running again before long.