This includes extensive experience in medium and large engine block repair - a critical service helping businesses in wide-ranging sectors keep their engines running smoothly. Engines are essential all manner of industries, so it is vital to get any repairs carried out swiftly to prevent operational disruption.

Common Industries

Medium, large or very large diesel engines are used for either propulsion or power generation. Metalock Engineering carry out repairs on diesel engines for many different types of businesses. Hotels, Banks, Hospitals, Factories, Land Fill Gas, Marine, Offshore, Land based power stations

Marine Industry: Diesel engines are used for propulsion and to generate on board power so reliable engine performance is critical. Marine environments can be harsh and challenging, which is why regular maintenance and swift engine block repairs are key.

Power Industry: Diesel engines are primarily used for power generation to drive large plant and equipment. The engine needs to provide continuous operation to meet power demands and this can put a strain on the engine block over time which can lead to failures.

Metalock Engineering provides a prompt and effective engine repairs at sea or on land anywhere in the world.

Common Issues With Engine Blocks

There are a number of issues that can arise with engine blocks that can affect the efficiency and performance of the engine and even cause total engine failure. Repairs need to be carried out swiftly to minimise downtime and avoid larger, more expensive repairs. The most common issues include:

Cracking: Cracks in the engine block can occur from thermal stress, manufacturing defects, and prolonged use. Cracks in the engine block can cause a loss of compression and leaks, which can impact the performance of the engine and will require immediate repairs.

Corrosion and wear: Corrosion and wear are common issues with engine blocks due to continuous exposure to coolant and oil and high operating temperatures. This can impact the efficiency and reliability of the engine.

Warping: The engine block can warp as a result of overheating or improper cooling. This can affect the alignment of the internal components, leading to engine failure and expensive repairs/replacements.

Poor Lubrication can also lead to crankshaft problems which can result in catastrophic engine failure.

These are all common issues with engine blocks that can compromise the performance of key industrial equipment. Therefore, timely and precise repairs are essential for maintaining engine performance.

Metalock Engineering’s Engine Repair Block Service

Here at Metalock Engineering, we specialise in carrying out engine block repairs that can prevent total engine replacement and help you keep costly downtime to a minimum. Using specialist repair techniques and technologies, we can restore your engine block to the original manufacturer’s specification and prolong the life of your engine, helping you avoid premature replacement. This service can include:

Metal Stitching

Metal stitching a cold repair technique for cracked or broken cast iron components without the need for heat (welding), which can cause further damage to the engine block. Metal stitching is more cost-effective than buying new cast parts, and it results in less downtime than other repair techniques. We have held the Lloyds Register Certificate for metal stitching repairs so you can rest assured knowing you are in safe hands when you choose Metalock Engineering as your repair partner.

The Casting Repair Process

The Metalock process is based on sound engineering principles which have been accepted for over 70 years.

- Holes drilled along the line of fracture, tapped and filled with studs.

- Holes drilled at right angles to the fracture.

- Holes drilled to form shape of Metalock keys.

- Layers of keys peened into metal-to-metal condition.

Broken Crankcase Door Repairs Stork Werkspoor Engine

A broken con rod breaking through the engine crankcase door casing causing catastrophic engine failure. The crankcase door was repaired using the Metalock cold metal stitching technique and our in situ machining team re-machined the crankpin journal diameter and fitted a new bearing. Problem solved all approved by Class

Crankcase door following conrod failure

Crankcase door following conrod failure

Base of door and bedplate

Base of door and bedplate

Door during repair using the Metalock method.

Door during repair using the Metalock method.

The full repair completed. Metalock also re-machined the crankpin bearing journal diameter.

The full repair completed. Metalock also re-machined the crankpin bearing journal diameter.

On-site Machining

Metalock Engineering can also perform onsite machining, meaning that engine block repairs can be carried out on-site as opposed to in a workshop. With advances in-situ repair techniques, this prevents the need to disassemble the engine and send away components for repair, helping to save both time and money.

RK 270 engine block

RK 270 engine block

Re-machining areas highlighted in green

Re-machining areas highlighted in green

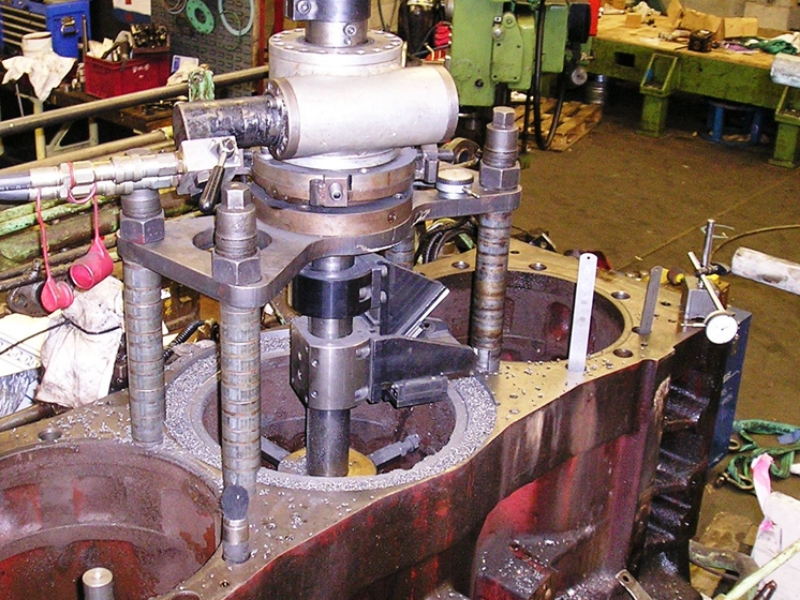

MaK engine upper liner machined before fitting a top hat make up ring returning the landing back to the original spec.

Machining complete awaiting fitting of make up ring

Machining complete awaiting fitting of make up ring

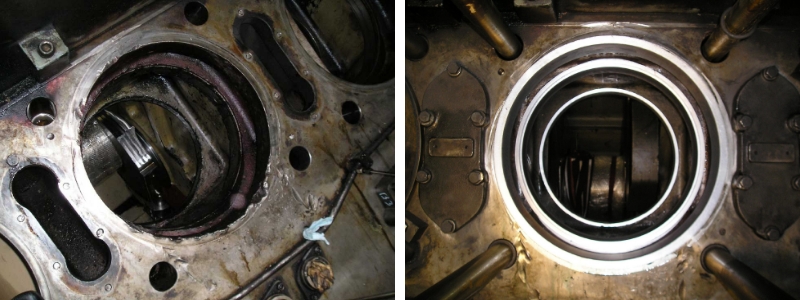

Cracked Lower Liner diameter repaired using the metalock method and re-bored by our on site machining department.

Cracked Lower Liner diameter repaired using the metalock method and re-bored by our on site machining department.

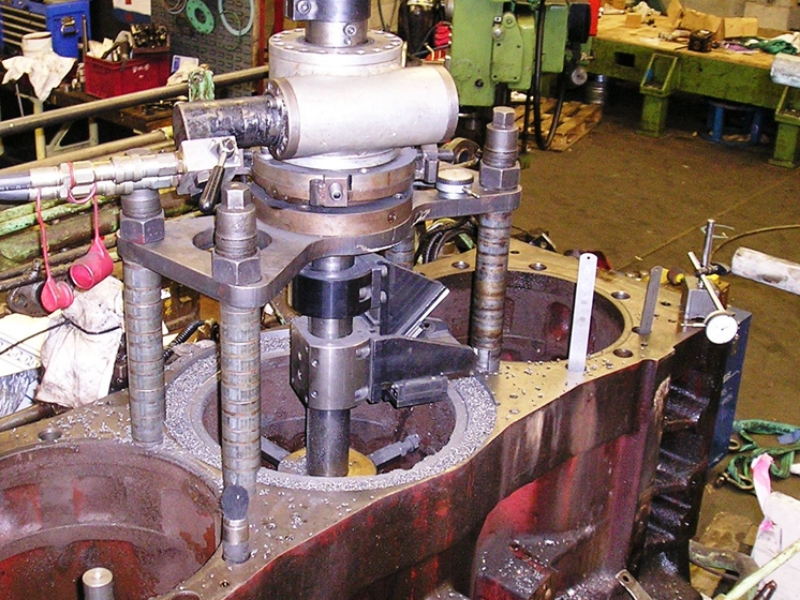

Honing liner bores

Honing liner bores

Global 24/7 Repair Service

One of the main reasons to choose Metalock Engineering for your engine block repair needs is the fact we offer a global 24/7 repair service. We serve over 100 countries around the world and have a team of highly skilled technicians strategically located and ready to travel at short notice. Additionally, we are available 24/7, 365 days a year, meaning that we can always respond quickly and can deploy someone to your location. This is important because it means that engine block repairs can be carried out quickly and without the need to send the engine block away for repairs. We can help keep downtime to a minimum so that you can save money and avoid lengthy operational delays.

Typical Diesel Engine Repair Examples

- Cold Metalock cast iron repairs on cracked or broken

engines and associated components (metal-stitching)

- Main bearing pocket transplants

- Refurbishment of upper/lower cylinder liner landing

face and bore areas

- Metal spray and re-machine badly worn, upper liner

landing surfaces

- Engine in line boring main bearing pockets

- Machine the main bearing and big end journals while the

crankshaft is still in the engine using orbital machining equipment

- Engine alignment

- Fusion welding of diesel engine cylinder heads

- Reconditioning of pistons, valves, and seats

- Crankshaft straightening in situ

- Crankshaft heat treatment in situ to reduce hardness values

Cracked Caterpillar 3606 Engine block - water jacket Metalock repair. Before and After.

Cracked Caterpillar 3606 Engine block - water jacket Metalock repair. Before and After.

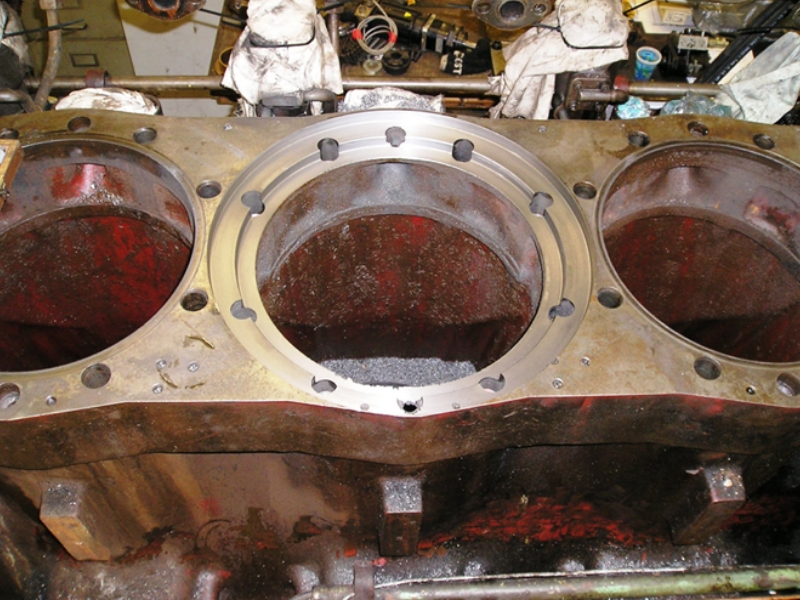

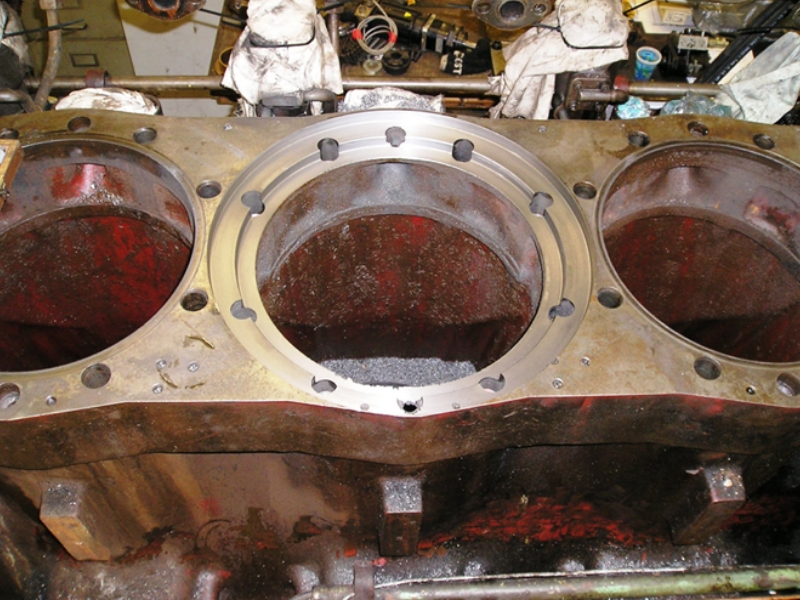

Damaged Wartsila 18V 38B engine block – Upper and lower liner reboring. Before and After.

Damaged Wartsila 18V 38B engine block – Upper and lower liner reboring. Before and After.

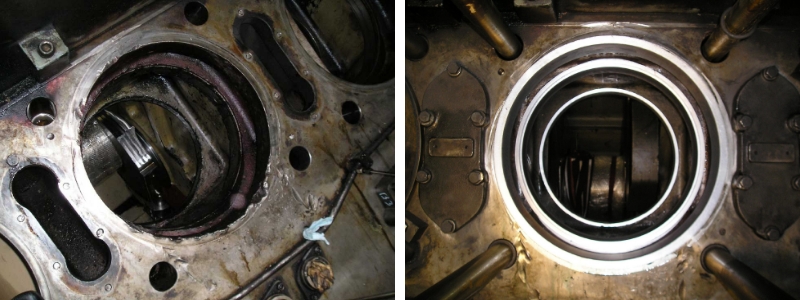

Cracked and damaged Wartsila Vasa 32 Engine block - liner housing repair. Before and After.

Cracked and damaged Wartsila Vasa 32 Engine block - liner housing repair. Before and After.

Contact Metalock Engineering for Engine Block Repairs

As the largest onsite engineering group in the world with over 120 years of experience, Metalock Engineering is the logical choice when it comes to engine block repairs. We have extensive experience carrying out engine block repair for businesses in wide-ranging sectors. We use advanced repair techniques that can get your engine fully operational before long, helping you save time and money.

Crankcase door following conrod failure

Crankcase door following conrod failure Base of door and bedplate

Base of door and bedplate Door during repair using the Metalock method.

Door during repair using the Metalock method. The full repair completed. Metalock also re-machined the crankpin bearing journal diameter.

The full repair completed. Metalock also re-machined the crankpin bearing journal diameter. RK 270 engine block

RK 270 engine block Re-machining areas highlighted in green

Re-machining areas highlighted in green

Machining complete awaiting fitting of make up ring

Machining complete awaiting fitting of make up ring Cracked Lower Liner diameter repaired using the metalock method and re-bored by our on site machining department.

Cracked Lower Liner diameter repaired using the metalock method and re-bored by our on site machining department. Honing liner bores

Honing liner bores Cracked Caterpillar 3606 Engine block - water jacket Metalock repair. Before and After.

Cracked Caterpillar 3606 Engine block - water jacket Metalock repair. Before and After. Damaged Wartsila 18V 38B engine block – Upper and lower liner reboring. Before and After.

Damaged Wartsila 18V 38B engine block – Upper and lower liner reboring. Before and After. Cracked and damaged Wartsila Vasa 32 Engine block - liner housing repair. Before and After.

Cracked and damaged Wartsila Vasa 32 Engine block - liner housing repair. Before and After.