Marine Engines Overview

Marine engines are the beating heart of the marine and offshore industry. Our expertise spans a wide range of in situ mechanical repair techniques designed to address the unique challenges of medium and large diesel engines.

Common Applications

As a critical element of the marine and offshore industry, there are many applications of marine engines, including:

- Commercial ships: Cargo ships, tankers, and container ships for the transportation of goods.

- Naval and military: Marine engines are used on warships and patrol boats.

- Passenger transport: Cruise ships and ferries use marine engines for efficient and reliable transport.

Common Marine Engine Issues

- Corrosion: Corrosion is a common issue with marine engines due to the harsh conditions of the marine environment.

- Vibrations and strange noises: Mechanical issues, such as propeller faults, bearing wear, or misalignment, can cause vibrations and strange noises.

- Overloading the engine:

Stress and overheating occurs when the engine operates consistently beyond its designed capacity

- Lubrication issues: Wear and tear is common when insufficient or contaminated lubricant is used.

Marine Engine Maintenance

Marine engine maintenance is critical to keep the engine in peak condition, prevent issues from arising, and prolong the life of the engine.

Metalock Engineering Marine Engine Repairs

Metalock Engineering has extensive experience carrying out marine engine repairs for several applications. Our repair services include:

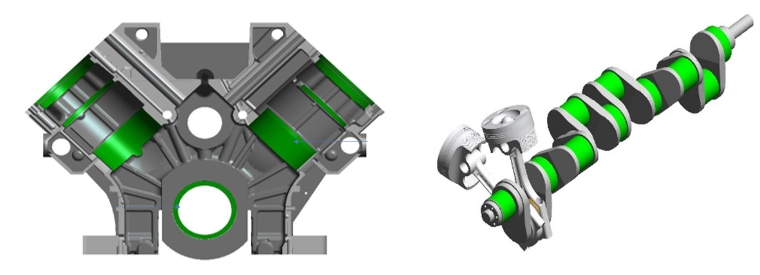

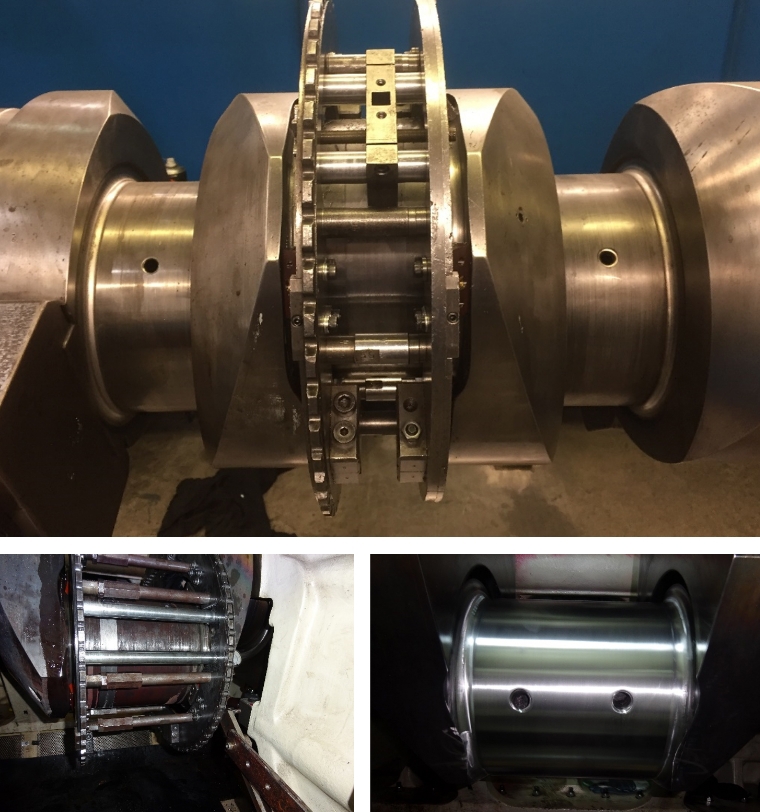

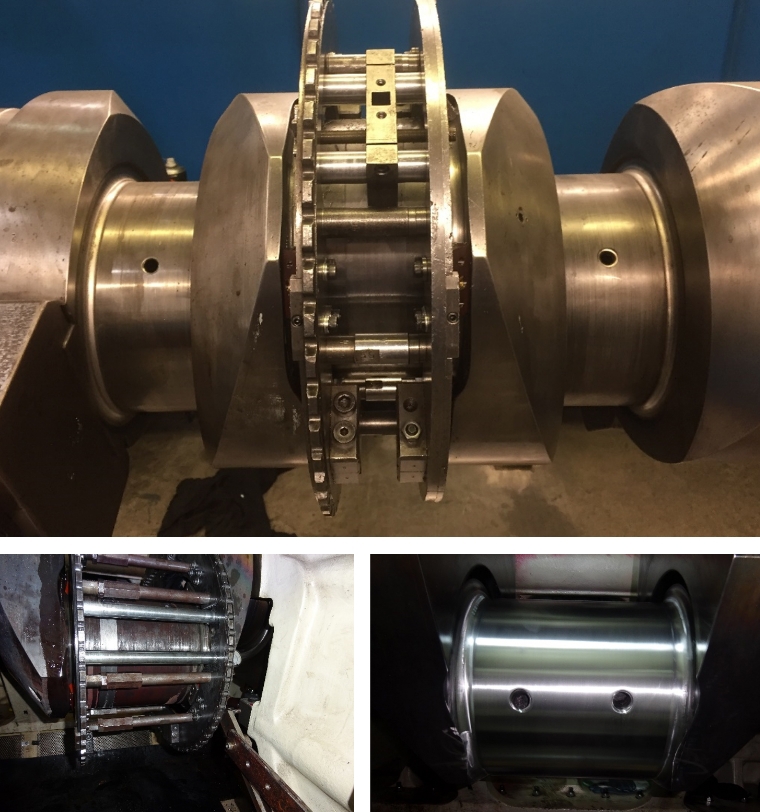

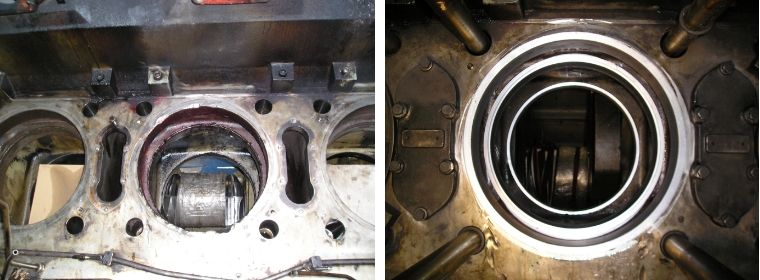

Crankshaft and Main Bearing Repairs

We can use specialist orbital machining equipment to machine and grind crankpins and main bearings on-site and restore components to optimum condition. We can also replace damaged bearing pockets to maintain the performance of your marine engine and extend its lifespan.

Crankshaft Heat Treatment to reduce hardness values and crankshaft straightening

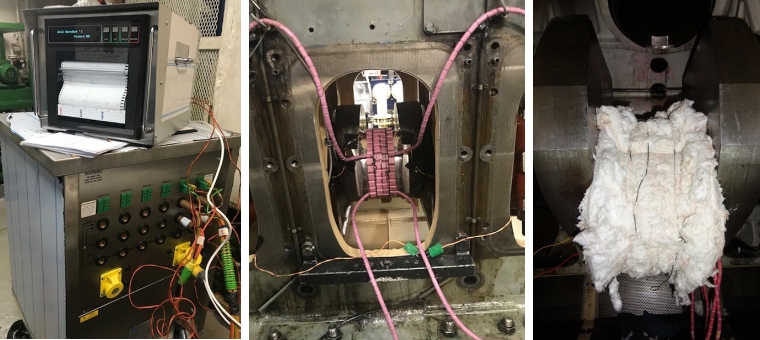

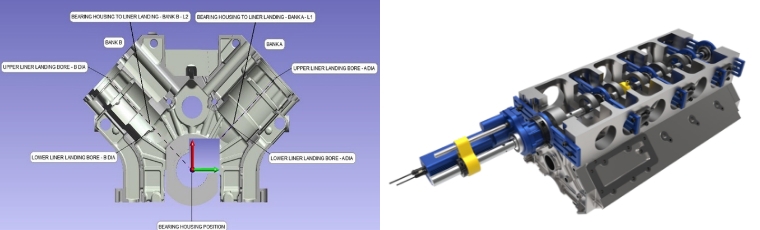

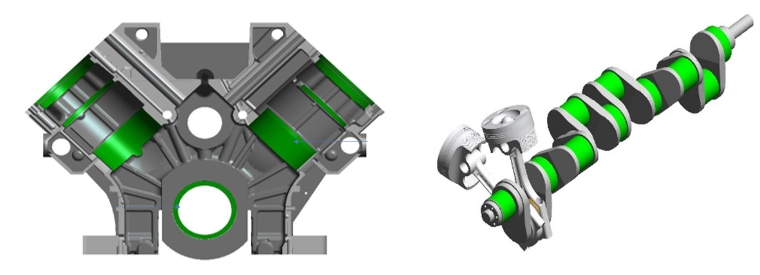

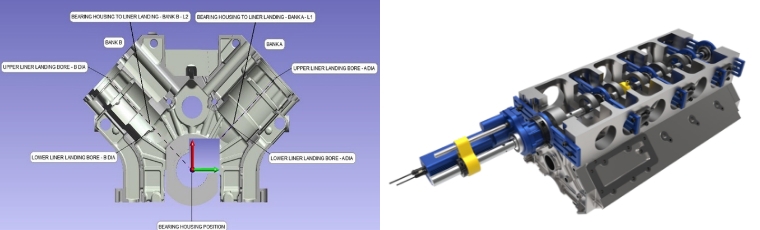

Cylinder & Liner Boring Services

We can refurbish worn landing surfaces to prevent leaks and maintain the efficiency of your marine engine. We can also help create a proper seal and prevent engine failure by repairing and machining the landing areas.

Alignment & Boring Services

Engine alignment can be performed to prevent wear and extend the lifespan of the engine. Line boring can also be performed to maintain alignment and can be performed on engines, stern tubes, and ‘A’ brackets.

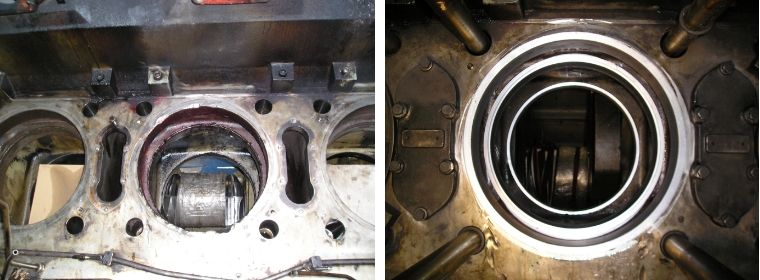

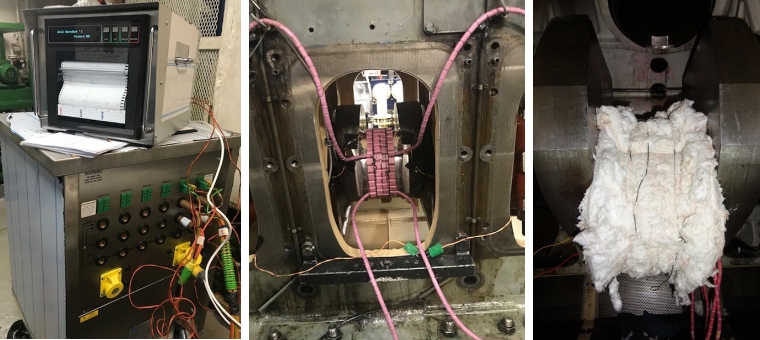

Cold Metalock Repairs on engine crankcase

Our advanced and patented Cold Metalock repair process involves using metal stitching to repair cracks without the need for welding. We can also use advanced welding techniques to repair critical engine parts to improve the performance and reliability of the unit.

Why Choose Metalock Engineering

We are confident that we are the right company for the job, having supported Merchant Marine and the Offshore industry since 1946. Over this time, we have gained extensive experience in marine engine repair, having helped customers in a wide range of industries facing different marine engine problems. Here are a few of the main reasons to choose Metalock Engineering for your marine engine repair needs:

Global Response

With a team of highly skilled engineers strategically placed at service centers around the globe, Metalock Engineering is always well-positioned to respond swiftly to your needs. Those in the marine and offshore industry are often located in hard-to-reach areas, but with our carefully placed technicians, we should get to you as soon as possible.

24/7 Support

We are also available 24/7 and every day of the year - we don’t take any time off here at Metalock Engineering. This means that you can call us at any moment, and we can be ready to travel at short notice to reach you.

On-Site Repairs

We can usually carry out marine engine repairs on-site. With many companies, you would have to dismantle the engine and send parts away for repair, but we use advanced techniques and technologies to carry out the work in situ. This is important because it means that work can be completed more quickly, and you can avoid the large costs involved in shipping engine parts.

Combining these reasons together, you can rest assured knowing that Metalock Engineering should be able to meet your marine engine repair needs quickly and get your engine up and running again before long. This means that you can prevent downtime, which costs the industry millions each year and can bring your operation to a halt.