One area we specialise in is orbital machining - a process used to machine circular surfaces around stationery shafts or components without the need for disassembly. This makes orbital machining useful in many industrial applications and enables businesses to keep downtime to a minimum. Keep reading to learn more about our orbital machining around stationary shaft services.

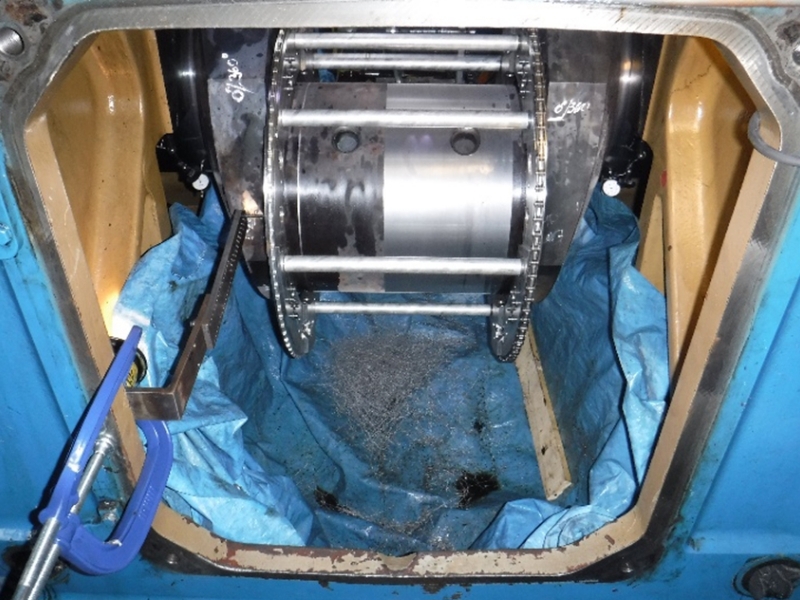

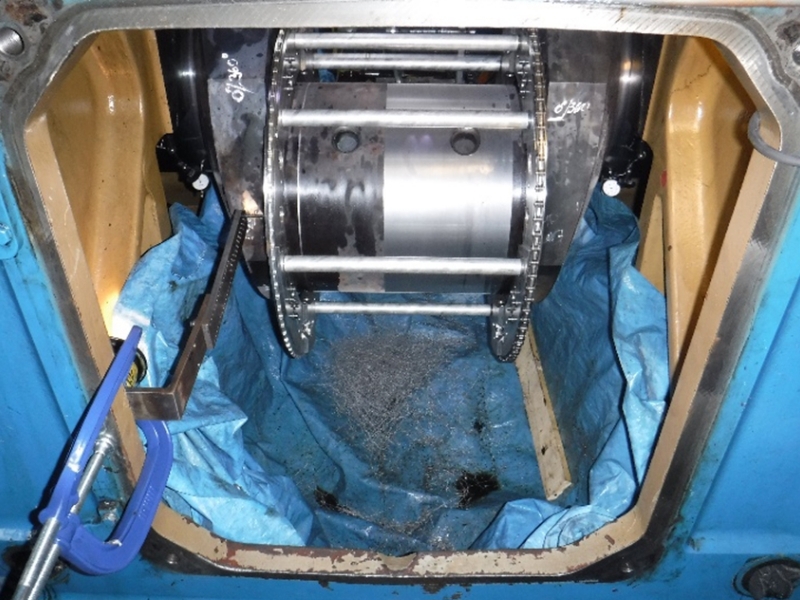

Orbital machining of Generator slip ring

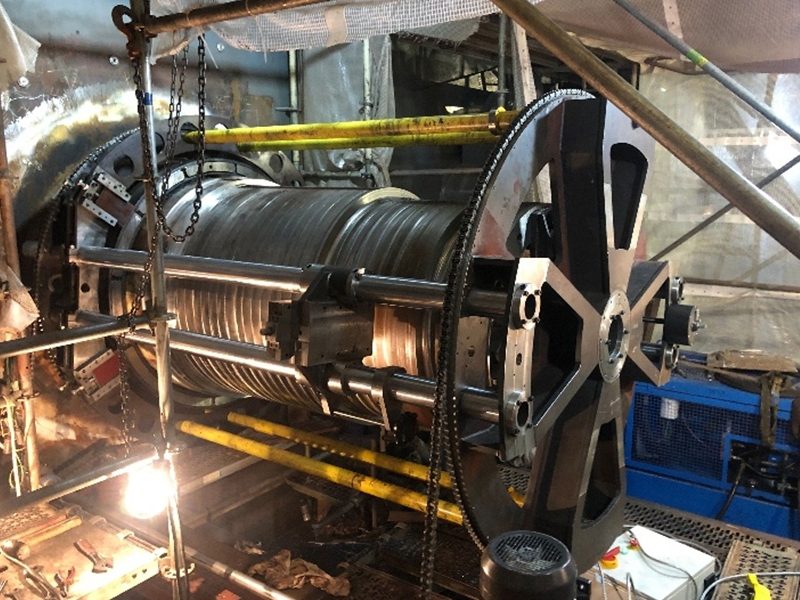

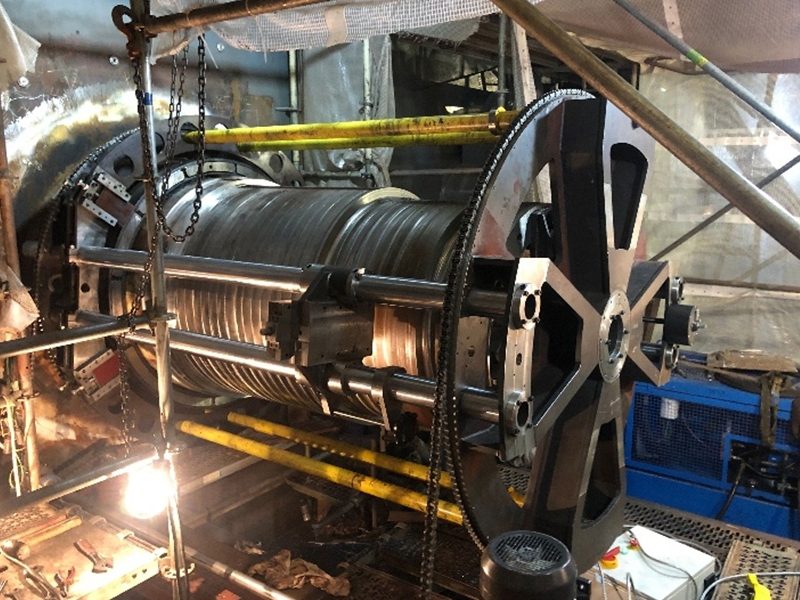

Orbital machining large diesel engine big end journal

What is Orbital Machining?

Machining involves removing material to create the desired shape or part, but this can be

challenging for circular surfaces, such as coupling faces and bearing housings. Orbital machining is a specialist technique of machining circular surfaces while the shaft remains stationary.

This technique works with the use of a cutting tool that moves in an orbit around the component, which allows for precise machining in confined spaces.

Why is Orbital Machining Needed?

Orbital machining is an important technique in a number of different industries for a few reasons. Equipment like turbines, pumps, and compressors can often develop wear and tear over time or become misaligned in mating surfaces, which impacts the performance of the equipment and can even cause complete failure.

Orbital machining can be used for restoring damaged surfaces. It can be used to repair worn,

corroded, and uneven circular surfaces without the need to dismantle surrounding components, which can restore the equipment to its original specification. In addition to this, orbital machining can be used for precise alignment to improve the performance of industrial equipment and prevent premature wear and tear. With the ability to conduct repairs on-site and without having to take equipment apart, orbital machining can also help industrial businesses avoid lengthy and costly shutdowns and complicated disassembly procedures.

Industries That Benefit from Orbital Machining

There are a number of industries that can benefit from our orbital machining services. These include:

- Marine: Orbital machining can be used to ensure the integrity of bearing housings and coupling faces used in ship engines.

- Manufacturing: Orbital machining can be used to restore alignment and function in heavy-duty machinery and production equipment.

- Mining: Orbital machining can be used to repair key components in mining and processing equipment.

- Oil & Gas: In the oil and gas sector, orbital machining can be used to repair all kinds of equipment in refineries, pipelines, and offshore platforms. This includes flanges, compressors, and valves.

The Benefits of Orbital Machining

Compared to traditional machining techniques, orbital machining has a number of unique benefits to consider:

- Versatility: This is a technique that can be used on a huge range of equipment and components used in many different industries.

- No dismantling of equipment: Orbital machining can be performed around the stationery shaft, which means that you do not have the cost or hassle of dismantling and transporting large or heavy machinery.

- Precision in place: Tight tolerances and accurate alignment are achieved within the need to remove the component from its installed position.

- Minimise downtime: A huge advantage of orbital machining is the fact that you can minimise downtime, which saves both time and money. This is because you do not have the downtime associated with taking apart equipment and transporting it.

- No damage risk: When you have to dismantle equipment and send it away for machining, there is always the risk of damage from transport and reinstallation. This is not an issue with orbital machining with the process taking place in situ.

Why Choose Metalock Engineering for Orbital Machining

So, why should you choose us for your orbital machining needs? We are considered a global leader in machining and on-site repairs and have extensive experience in many industries. Here are a few reasons why you should choose us:

Expertise

We are experts in the field with 120+ years of experience in industrial repairs and machining. We have developed many advanced repair techniques, so you know you are getting the best withMetalock Engineering. All of our technicians are highly trained and can perform orbital machining safely and to the highest standard.

Advanced Tech

Here at Metalock, we also use the very latest orbital machining tools to deliver precise and high-quality results for your exact specifications. Technology is constantly evolving, and we are proud to be pioneering with the use of state-of-the-art technology.

Global Presence

We also have a global presence and serve over 100 countries. We have our highly skilled

technicians strategically positioned around the world and ready to travel at short notice so we can send someone close to you to keep downtime to a minimum.

24/7 Support

We do not take a day off at Metalock Engineering and understand that machining and repairs often need to be completed at unexpected times. This is why you can contact us 24/7, and we will respond to resolve your issue as swiftly as possible. Again, this can minimise downtime and will help you get up and running again before long, which will help you avoid the costs of downtime and keep up with production demands.

Cement Mill Bearing Journal recovery 36 inches diameter x 36 inches long

Contact Metalock Engineering for Orbital Machining Needs

For any business needing machining around a stationary shaft or circular component, we are here to help. Metalock Engineering is a global leader in critical equipment repairs and maintenance,

including orbital machining services. Orbital machining is an advanced technique that can provide accurate, efficient, and cost-effective solutions.

Whether you need orbital machining to restore damaged surfaces of key equipment or you need to ensure precise alignment, we can help. This technique can prevent you from taking equipment apart and sending it away, which means that it can be much faster than alternative solutions and reduces operational interruptions. In addition to this, orbital machining can extend the life of your critical equipment, helping you make long-term savings.