Rotary Table Repair

Get your rotary table back to normal operation and avoid costly downtime with our repair services. Our advanced techniques can maintain your machinery’s precision and functionality.

At Metalock Engineering, we deliver rotary table repair services that can be tailored to meet the complex demands of various industries. Whether you operate in the marine, steel, mining, or any other applicable sector, our team can address various mechanical issues.

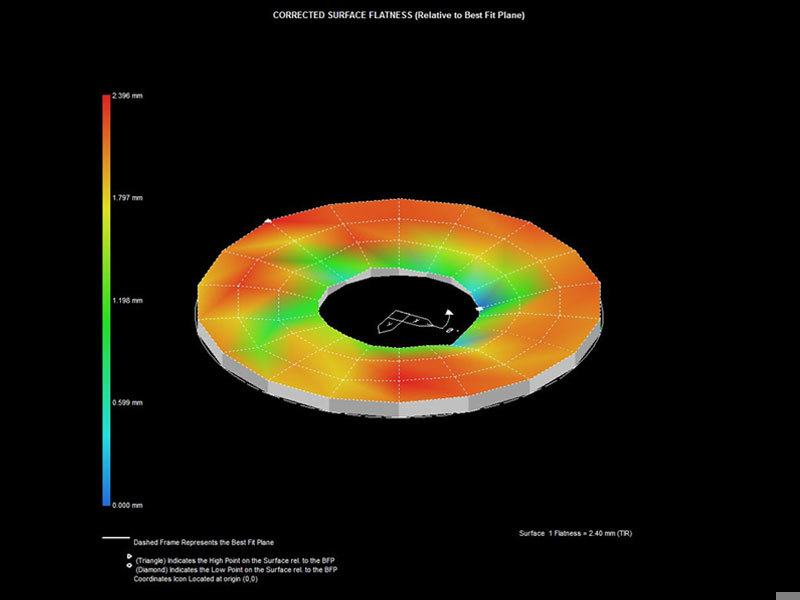

On-site CNC machining allows for precise modifications and repairs, including resurfacing the table or correcting geometrical inaccuracies. Our metrology service provides accurate measurements that can help achieve precise specifications required for optimal performance, while laser guided machining gives us extra accuracy when working on large or complex rotary tables.

Placing an emphasis on precision and efficiency, we can get your rotary table back in operational condition.

Raw Mill Vertical Roller Table 5 meters outside diameter (660 mm inside diameter), Remove 3 mm from surface

Raw Mill Vertical Roller Table 5 meters outside diameter (660 mm inside diameter), Remove 3 mm from surface

Metalock Engineering has a global presence in the field of mechanical engineering and repair. Our extensive 87+ years of experience spans a diverse range of industries, equipping us with the ability to handle intricate, demanding rotary table repair projects. As an example, this includes machining a 5.2m diameter rotary base table for use in the cement industry for which we created a bespoke machining rig to complete the job.

With the expertise and standards we possess, we can achieve high standards of quality and reliability with our rotary table repairs.

From knowledge across various sectors to global availability, these are distinct advantages behind choosing Metalock Engineering for your rotary table repair needs. We are able to provide fast in situ responses and repairs, coming up with bespoke solutions to your problems. This can assist with meeting current and future operational demands with your equipment.

Additionally, our worldwide response means we can get to where you need us, quickly.

If you require assistance with repairing your rotary table, contact us today. We will highlight how our services can help get your equipment back to its best.

Get in contact

How can we help you? We offer a 24/7 worldwide emergency response. Please select from the options below to contact us.

Submit an Enquiry Office Locations Quick Contacts Careers