This includes extensive experience in ship propeller repair services. Our expertise lies in repairing specific components rather than entire systems, which means that we can help in the repair of different ship propeller issues that those in the marine and offshore industries face. This also means that we can help you to avoid full propeller replacement. These services can save you from premature propeller replacement, which will save you a lot of money in the long run.

Why Propeller Repairs & Maintenance Are Key

Propellers play a critical role in the propulsion and maneuverability of any vessel. Therefore, any issues with the propeller can impact the efficiency, performance, and safety of the vessel. Propellers are also complex pieces of equipment with many issues that can arise that can stop the propeller and entire vessel from working and create a potentially dangerous situation. A few of the most common propeller issues we see include:

Cavitation: Low pressure on the blade surface causes water to vaporize, creating bubbles that generate shock waves that can cause pitting and erode the surface.

Corrosion: Saltwater environments can cause corrosion, particularly on metal blades. This affects the structural integrity of the propeller and its efficiency and propeller hub replacement.

Blade damage: Blade damage can occur when the propeller hits underwater items, such as rocks or debris. This can impact the performance of the propeller and may require repairs or replacement.

Biofouling: An accumulation of marine organisms, such as barnacles, can affect the efficiency of the propeller and increase fuel consumption.

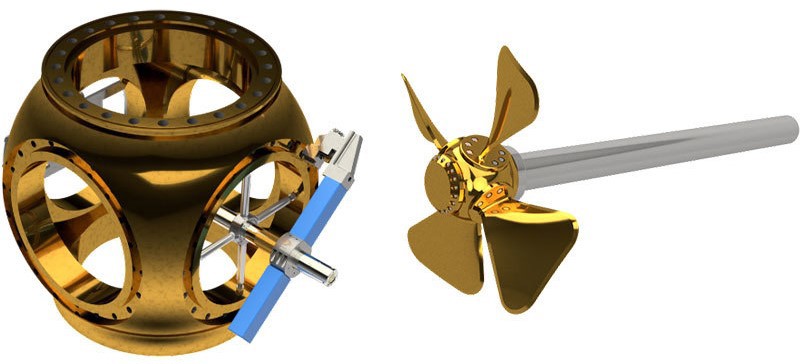

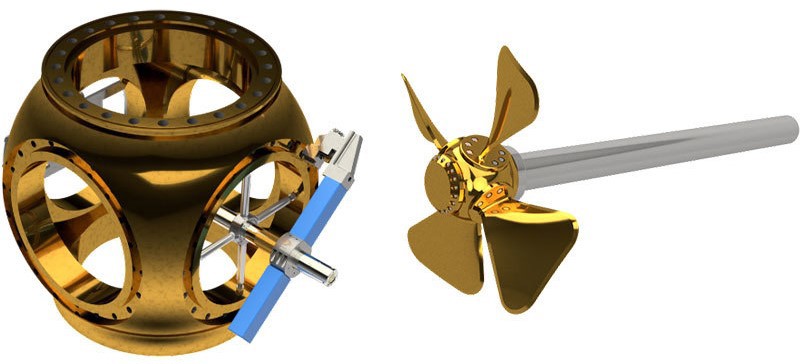

Propeller Repair Services

As such a key component of a vessel, it is vital that you have propeller repair and maintenance services that you can trust. Here at Metalock Engineering, we are proud of our specialist engineering services that can be used in propeller repairs using different techniques and specialist equipment. We leave full propeller repairs to the manufacturer, but we can help with the recovery of worn propulsion components.

As mentioned, we are the largest on-site machining group in the world. We can complete the work in the drydock. This means that you do not have to dismantle the propeller, send away components, and wait for them to come back. This will save you a huge amount of time and money as we can quickly come to you and carry out the repair in situ.

We can carry out a wide range of propeller repairs for you, including:

As mentioned, cavitation is one of the most common issues we see at Metalock Engineering. This is why we recommend looking out for early signs of cavitation damage so that we can fix the problem before it becomes much larger and harder to resolve. We can pre-machine the affected area, rebuild it with metal spray, and then re-machine it back to its original dimension.

Why Use Metalock Engineering For Propeller Repairs?

We are confident that we are the right company for the job thanks to our extensive experience in propeller repair services and helping customers in various sectors within the marine industry. No matter what type of vessel you have, our repair service will bring a wide range of benefits, and you are sure to be impressed with our service.

One of the key reasons to use Metalock Engineering for your propeller repair needs is the fact we offer a 24/7 365 global response service. Our technicians are strategically placed around the world and ready to travel at a moment’s notice, which means that they can come to you quickly, no matter where you are.

Additionally, the fact that work can be carried out in situ as opposed to in a workshop brings a few benefits. This means that work can start as soon as our technicians arrive at your vessel. This means that you can also complete the work much faster, preventing downtime and getting you fully operational again before long. This can save you a huge amount of time and money - both of which are key for marine shipping company operators.

Metalock Engineering, you can help to prolong the life of your propeller system. This will prevent the need for premature propeller replacement, which can save you a huge amount of money in the long run.

Metalock Engineering has served and supported the Naval and Merchant Marine and the Offshore industry since 1946. This means that we have seen it all over the years and help save millions in lost revenue throughout the industry each year. You know you are in safe and experienced hands when you use Metalock Engineering for your propeller repair requirements.

Problems with the propeller can bring your vessel to a grinding halt. There are many issues that can arise in a propeller, but this does not necessarily mean that you must replace the entire unit. Here at Metalock Engineering, we are experts when it comes to component repairs, so we can pinpoint the issue and restore your propeller to its original condition.