We are the largest on-site machining engineering group in the world. We have a team of highly skilled technicians who usually carry out repairs on-site, helping save you money and restore your components quickly and efficiently. Keep reading to learn more about our turbine casing repair services.

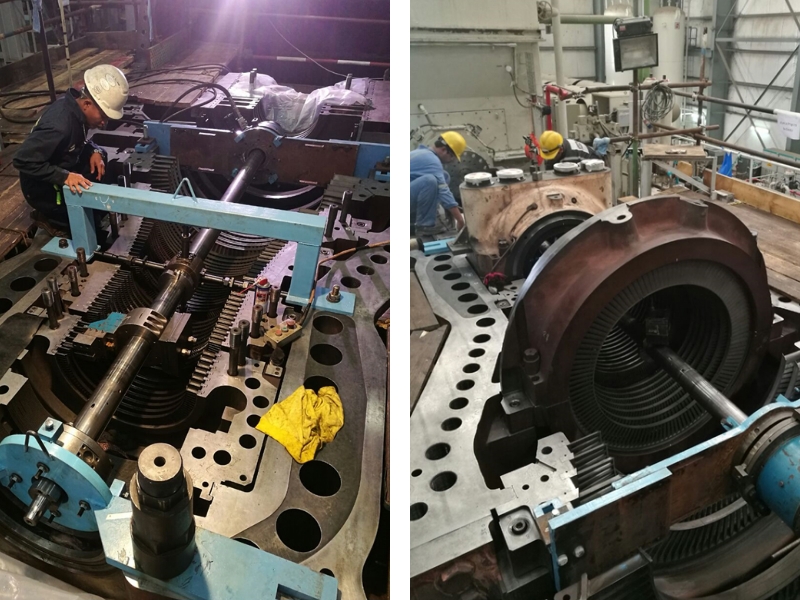

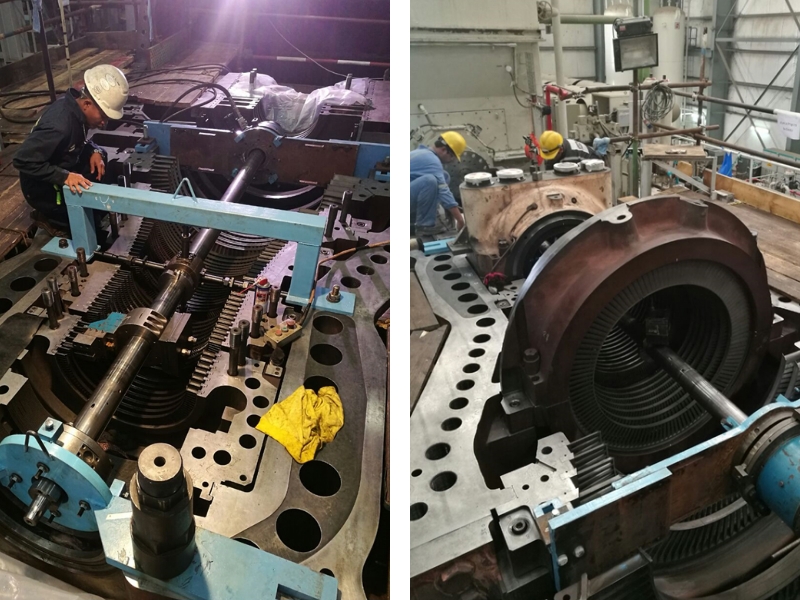

4 images of Turbine split joint being re-machined in India

What is a Turbine Casing?

A turbine casing is an external shell that contains and directs the working fluid, such as water or steam. Turbine casings are often made out of cast iron, cast steel or fabricated steel. Turbine casings play a critical role in the overall performance of the turbine, so it is vital that they are fully operational at all times. However, turbine casings are also subject to high heat and stress levels during operation which means that there are issues that can arise.

Common Issues with Turbine Casings

Leading on from this, there are a handful of issues that can arise with turbine casings that can impact the performance of the turbine and even stop it from working entirely. A few of the most common issues that are seen with turbine casings include:

Wear & Tear: Wear and tear is the most common issue with turbine casings. Continuous operation and exposure to high pressure super-heated steam and/or gases can cause wear and tear, which affects the overall integrity of the component.

Corrosion: Turbine casings are often continuously exposed to high levels of humidity. This can lead to corrosion that can weaken the turbine casing.

Cracks & Fractures: Cracks and fractures can occur as a result of thermal cycling, fatigue, and operational stress. These cracks and fractures can quickly grow, which can lead to extensive damage and complete failure.

Seal Damage: Turbine casing glands and seals can become damaged, which can result in steam leaks. These leaks can impact the efficiency of the turbine and increase the risk of damage to key internal components.

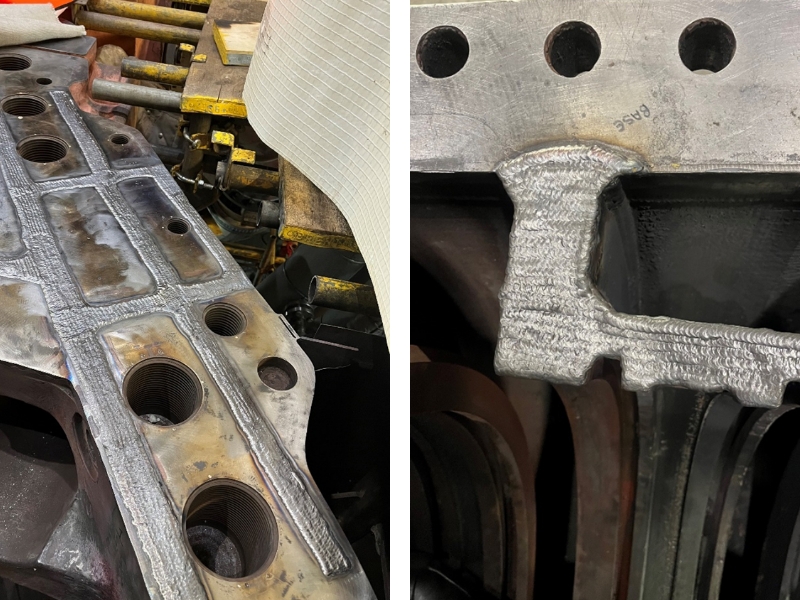

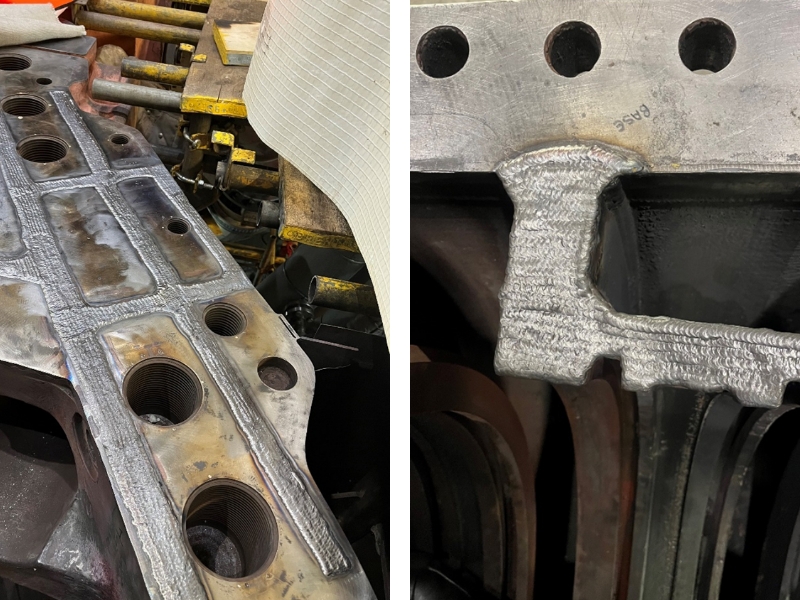

Fixed blade serrated grooves being re-machined following casing weld repairs in Czech Republic

Industries Where Turbine Casings Are Found

These days, turbines are integral part of all industries Here are a few of the main industries where turbine casings are found:

Power Generation: Both gas and steam turbines play an important role in power plants by producing electricity from energy produced by combustion gases or steam.

Oil & Gas: Turbines are used in the oil and gas sector to drive compressors, pumps, and generators in refineries and offshore platforms for energy production.

Marine: Turbines are used in the marine sector to provide power used for propulsion.

Turbine Casing Repair Services from Metalock Engineering

Small Industrial turbine casing being re-bored in the middle east.

Metalock Engineering has expertise in turbine casing repairs for businesses in wide-ranging industries. We use advanced repair techniques that can quickly and efficiently restore your turbine casing to its original specification, helping you save money and prolong the life of your key industrial equipment.

On-site Repairs

We can usually carry out repairs on-site, which means that you do not have the cost and logistical challenges of dismantling your turbine and sending parts away for repair. This minimises disruption to your daily operation and helps keep downtime to a minimum.

Patented Metal Stitching

We have a patented metal stitching repair technique that can be used to repair cracks and fractures in turbine casings. This is a cold repair technique, which means that there is no risk of warping or damage, which is common with welding repair techniques. This repair technique can restore the structural integrity of metal components and is far more cost-effective than buying new parts.

On site machining / Welding / Metal Spraying

The worn or corroded areas within the turbine casings can be pre-machined to remove damage and wear, then built back up using either weld repairs or metal spraying repairs before being re-machined back to the original specification. These are very effective repairs that can be carried out in situ on diaphragm and blade locations, gland areas and split joint faces.

Welded split joint (left) and welded gland area (right) before final split joint re-machining.

Metrology/Alignment services: to check the turbine is aligned correctly and to guide our on-site CNC milling and boring machines used in the restoration of damaged casings.

Global Presence

We also have a global presence serving over 100 countries (and counting). We have our team of highly skilled technicians located all around the world, and they are ready to travel at short notice, which means that we can send the technician best positioned to reach you quickly. This will help keep downtime to a minimum and save the cost of having to send the part away for repair.

24/7 Availability

At Metalock Engineering, we understand that industrial equipment can break down at any moment. This is why we have a 24/7 service so that we can respond as quickly as possible to your emergency. We also work 365 days a year so you can contact us at any time, and we will respond.

Safety

Of course, safety is a top priority when it comes to industrial repairs. All of our technicians are highly trained and have a developed sense of safety awareness, which means that all repairs are carried out safely and to the highest standard.

Experience

When it comes to the repair of key industrial components, you want to know that you are in safe hands. Metalock Engineering has over 70 years of experience in technically demanding machining engineering and mechanical repair projects. All of our technicians are trained in our advanced techniques and technologies and have experience in carrying out repairs in various industrial environments.

Turbine Inner casing machining modification

We are available 24/7 and have technicians ready to travel to you at a moment’s notice. With proven expertise in quality repairs, maintenance, modifications, and upgrades all around the world, you know you are in safe hands when you choose Metalock Engineering for your turbine casing repairs.